manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

Brushs & Wheels

Leading Manufacturers, Exporters and Wholesaler of Valgro Combi Flap Brush, Valgro Cut N Polish Exl Deburring Finishing Wheel, Valgro Dot Deburring Disc Brush, Valgro Finishing Flap Brush, Valgro Flexible File Disc Brush, Valgro Metal Strip Coil Cleaning Brush, Valgro Poly Bond Polishing Wheel, Valgro Turbine Disc Brush, Valgro Wide Face Disc Cleaning Brush and Valgro Wide Face Finishing Brush from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Industrial Brush |

| Material | Abrasive Flaps |

| Color | Brown |

| Packaging Type | Box |

| Application | Metal Polishing |

| Size | 100mm to 500mm |

| Brand Name | Valgro |

The Valgro Combi Flap Brush is a high-performance abrasive flap wheel designed for consistent surface finishing across flat, curved, and complex-shaped components. Built with interleaved layers of coated abrasive strips and a heavy-duty backing material, it delivers a high material removal rate and a uniform scratch pattern — ideal for stainless steel, mild steel, aluminium, brass, and other alloys.

OverviewThis innovative brush features alternating abrasive and backing layers that maintain tool stability and eliminate the “lay-over effect” often seen in conventional flap wheels. The design ensures improved consistency, extended lifespan, and a uniform finish across all types of surfaces. It is compatible with hand tools, bench grinders, and both automatic and semi-automatic finishing machines.

Key Features-

Interleaved construction with coated abrasive strips and durable backing layers

-

Available in various grit sizes, hardness levels, and abrasive types to suit multiple applications

-

Produces a linear, uniform scratch pattern ideal for decorative or technical finishes

-

High stability at varying operating speeds, ensuring even surface contact

-

Suitable for manual, mechanical, and robotic finishing setups

-

High cutting efficiency with a uniform surface finish

-

Eliminates surface inconsistencies and uneven wear

-

Reduces rework and finishing costs due to extended tool life

-

Offers excellent flexibility for use on both flat and contoured surfaces

-

Delivers consistent quality and appearance across large production runs

-

Decorative finishing and surface preparation on stainless steel, aluminium, and non-ferrous metals

-

Cleaning, deburring, blending, and edge rounding of fabricated parts

-

Achieving hairline, satin, or brushed finishes on large panels or profiles

-

Weld removal and surface conditioning before coating or polishing

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Valgro |

| Shape | Round |

| Outer Diameter | 150mm to 350mm |

| Wheel Width | 12mm to 300mm |

| Type | Deburring Finishing Wheel |

| Material | Non Woven Adrasive |

| Application | Deburring And Finishing of Matels |

The Valgro Cut N Polish EXL Deburring & Finishing Wheel is a high-density, non-woven abrasive wheel engineered to rapidly remove burrs, clean edges and deliver a polished surface finish on metals, composites and glass. It’s ideal for laser-cut, punched, formed or machined parts where consistent surface quality and edge condition are critical.

OverviewThis wheel combines deburring, edge-radius formation and polishing in one operation. It features a solid, dense construction and conformable design to maintain effective contact even on complex-shaped parts or robotic end-of-arm tools. Typical users include manufacturers of aerospace components, medical instruments, decorative hardware, aluminium extrusions, and stamped/fabricated metal parts.

Key Features-

Solid, dense non-woven construction designed for high consistency and long life

-

Conformable design to maintain contact with contoured surfaces without gouging or undercutting

-

Suitable for a wide range of materials including metals, composites and glass

-

Engineered for smooth wear to keep fresh abrasive exposed continuously

-

Effective especially on heat-sensitive substrates thanks to minimal heat build-up

-

Achieves deburring and finishing in one step — reducing process time, labour and equipment cost

-

Delivers a smooth, polished finish that enhances aesthetics and reduces secondary polishing

-

Minimises risk of distortion, gouging or surface damage thanks to conformable, controlled removal action

-

Optimises productivity and tool life with controlled wear and consistent results

-

Supports complex part geometries and automated finishing systems

-

Deburring and finishing of laser-cut, punched or stamped metal parts

-

Edge finishing on machined components such as blades, housings, fasteners, extrusions

-

Cosmetic surface preparations for architectural hardware, medical instruments, aerospace components

-

Finishing operations where one tool must accomplish burr removal, smoothing and surface polish

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Deburring Applications |

| Color | Black |

| Type | Deburring Disc Brush |

| Size | 150mm To 400mm |

| Shape | Round |

| Brand Name | Valgro |

| Material | Abrasive Nylon |

The Valgro Dot Deburring Disc Brush is an economical and efficient solution for light deburring, surface finishing, and edge preparation. Its unique dot-style construction provides flexibility and precision, making it ideal for removing small burrs, cleaning tight areas, and improving part surfaces without damaging edges or corners.

Overview

This brush is designed for applications that require consistent, light-duty surface finishing. Its flexible design allows it to reach small holes and complex geometries while maintaining uniform edge quality. The brush provides fast cycle times, stable performance, and a smooth finish—making it suitable for both manual and automated operations.

Key Features

Dot or punch-style disc construction for controlled, light deburring.

Excellent flexibility for accessing tight or intricate areas.

Maintains consistent brush shape during use for reliable performance.

Suitable for CNC machines, robotic arms, and automated finishing systems.

Cost-effective tool with long service life for small-scale deburring operations.

Benefits

Achieves smooth, clean edges with minimal material removal.

Reduces production time and manual labor.

Ensures consistent surface quality across multiple components.

Prevents edge rounding or gouging on delicate parts.

Ideal for small and medium-volume finishing applications.

Typical Applications

Removal of light burrs from punched or laser-cut sheet metal parts.

Edge finishing and surface smoothing of brackets, flanges, and housings.

Cleaning small holes, slots, or complex profiles.

Suitable for light deburring on thin metal or precision-machined parts.

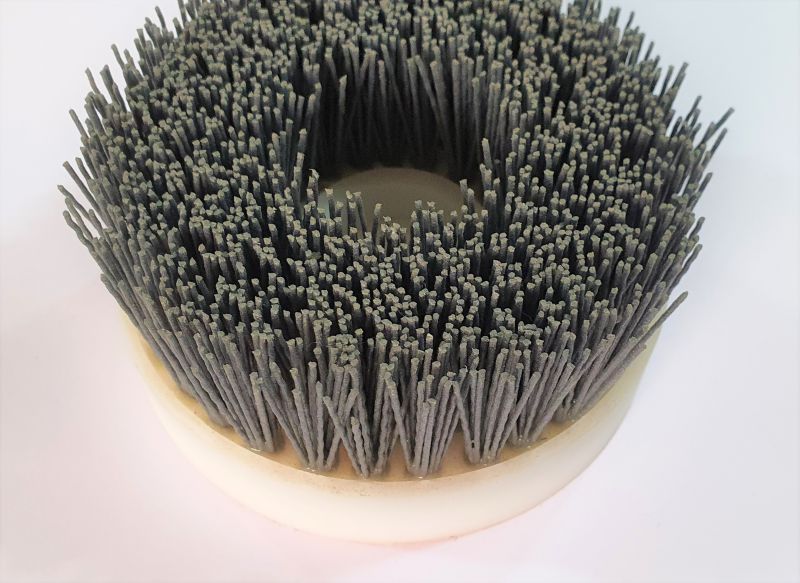

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Finishing Brush |

| Material | Abrasive Flaps |

| Packaging Type | Box |

| Application | Finishing Metal Surfaces |

| Size | 150x25mm |

| Brand Name | Valgro |

| Max RPM | 3200 RPM |

The Valgro Finishing Flap Brush (Valgro-Fynex) is designed for finishing curved and irregular-shaped parts where standard abrasive wheels struggle to reach. It provides consistent surface treatment across difficult geometries, delivering uniform scratch patterns on soft metals, aluminium, plastics or wood, and ideal for cosmetic finishes as well.

OverviewThe flap brush is fully impregnated with abrasives, built with an open-web construction to maintain flexibility, conformability and airflow. Its design ensures longer life, reduced loading, and better finish quality even when used wet or dry.

Key Features-

Fully abrasive-impregnated flap brush for extended life and performance

-

Open-web construction for flexibility and conformability to curved or irregular parts

-

Designed for use on soft materials like aluminium, plastic, wood, and non-ferrous metals

-

Operable in wet or dry conditions

-

Capable of running at higher speeds without undercutting or gouging

-

Produces uniform finishes with no skip-marks or inconsistent patterns

-

Increases productivity by delivering faster results and longer brush life

-

Reduces wastage and rejects thanks to better control of scratch pattern and finish quality

-

Versatile: one tool handles curved parts, difficult shapes, and multiple materials

-

Improves finishing quality especially on complex parts or materials prone to chatter or loading

-

Cosmetic surface finishing of aluminium or soft metal components

-

Finishing of plastic or wood parts where a uniform scratch or brushed finish is required

-

Irregular parts fabrication where corners, curves or contours make standard wheels ineffective

-

Pre-coating or pre-finishing operations where quality surface appearance is critical

| Business Type | Manufacturer, Exporter, Supplier |

| Frame Material | PVC |

| Shape | Round |

| Type | Industrial Brush |

| Material | Nylon Filament |

| Application | File Disc Cleaning |

| Size | 150mm to 400mm |

| Brand | Valgro |

The Valgro Flexible File Disc Brush is engineered for light-duty deburring, edge rounding, and surface finishing of stamped, laser-cut, or formed metal parts. Its flexible filament design ensures gentle yet effective burr removal while maintaining precise control and uniform surface quality.

Overview

Perfect for intricate components, this brush easily adapts to complex shapes and contours. It reaches tight areas and fine details without damaging the base material, providing a smooth, even finish ideal for small and medium-sized metal parts. Designed for both manual and automated setups, it delivers efficiency and consistency in high-volume operations.

Key Features

High-flexibility design for smooth finishing on complex shapes

Uniform edge rounding and controlled material removal

Available in multiple grit sizes for various surface requirements

Compatible with CNC, robotic, and manual polishing systems

Maintains shape and performance over long operational cycles

Benefits

Provides consistent, high-quality finishes with reduced manual effort

Enhances edge smoothness and product appearance

Extends tool life and reduces maintenance downtime

Improves overall productivity in finishing processes

Typical Applications

Light burr removal from stamped or laser-cut components

Edge rounding for flat or formed sheet metal parts

Cleaning and finishing of precision parts with tight geometries

Ideal for use in automotive, appliance, and sheet metal industries

| Business Type | Manufacturer, Exporter, Supplier |

| Shape | Round |

| Size | 300mm to 500mm |

| Brush Grade | CRS and MED |

| Product Type | Cleaning Brush |

| Material | Non Woven Abrasive |

| Usage | Coil Cleaning |

| Brand | Valgro |

The Valgro Metal Strip Coil Cleaning Brush is a high-performance tool designed for effective cleaning, descaling, and surface preparation of metal strips and coils. It efficiently removes oil patches, rust, mill scale, and oxide layers, delivering a uniform surface ready for coating, painting, or further processing. This advanced brushing solution enhances surface quality while significantly reducing chemical pickling costs.

OverviewDuring metal strip or coil production, surface imperfections such as oxide films, carbon residue, and rust can compromise finish quality. The Valgro Metal Strip Coil Cleaning Brush solves these issues through precision brushing technology that ensures consistent cleaning and improved adhesion for coatings. Field applications show that chemical pickling costs can be reduced by up to 70–75% by incorporating Valgro’s brushing system.

Key Features-

Available in multiple diameters (300 mm to 500 mm) and widths (400 mm to 2500 mm).

-

Manufactured in various hardness levels and grit sizes for different metal types and finishes.

-

Long-life impregnated brush construction for extended operational use.

-

Temperature-resistant with high edge stability for uniform, reproducible surfaces.

-

Self-dressing design maintains cleaning quality and reduces brush replacement frequency.

-

Provides a uniform cleaning effect, improving coating adhesion and surface appearance.

-

Achieves rust- and oxide-free surfaces, enhancing overall product quality.

-

Reduces chemical pickling costs by up to 75%.

-

Improves production efficiency by reducing downtime and rework.

-

Environmentally friendly – lowers chemical usage and disposal requirements.

-

Cleaning and polishing of hot-rolled (HR) and cold-rolled (CR) steel strips.

-

Preparation of aluminum, galvanized, or coated metal strips before finishing.

-

Integration into coil-to-coil processing and metal surface preparation lines.

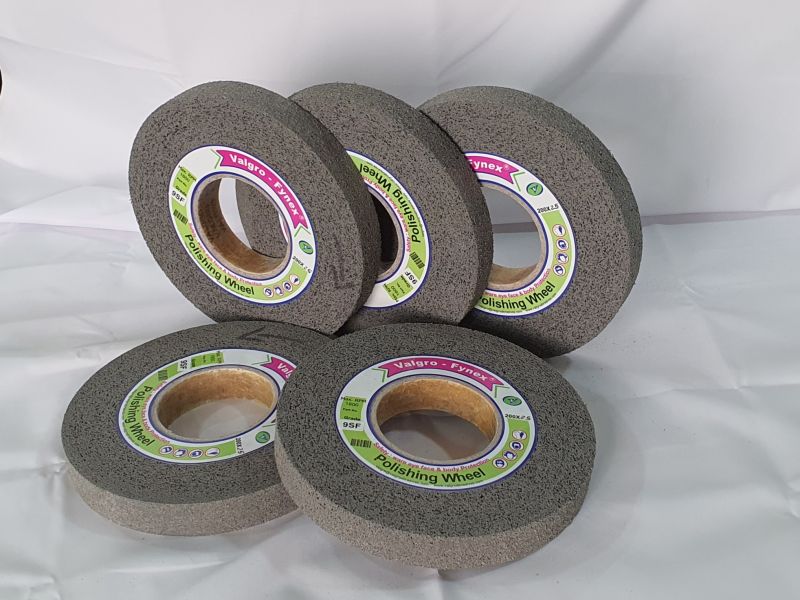

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polishing Wheels |

| Material | Non Woven Abrasive |

| Color | Brown |

| Application | Polishing Metal Surfaces |

| Outer Diameter | 25mm to 350mm |

| Brand Name | Valgro |

The Valgro Poly-Bond Polishing Wheel is a premium non-woven abrasive wheel designed for fine polishing, burr removal, and finishing of metals, alloys, and high-precision parts. The wheel is constructed with a dense, conformable polyurethane matrix impregnated with abrasive grains, enabling it to maintain contact with complex shapes while delivering a uniform, high-quality finish.

OverviewUnlike conventional flap wheels or coated-abrasive discs, the Poly-Bond wheel features a stable construction that minimizes gouging or undercutting, making it ideal for precision finishing operations on heat-sensitive substrates. It handles metals, composites, and glass with ease, allowing one tool to cover multiple materials and tasks.

Key Features-

Dense, polyurethane-bonded abrasive construction delivers long life and consistent finish.

-

Conformable design maintains contact on curved or irregular parts, ideal for robotic or hand-held finishing.

-

Suitable for a wide range of materials — metals, composites, glass.

-

Minimizes heat build-up, reducing risk of discoloration or warping in sensitive materials.

-

Available in a variety of diameters, widths, and grades (coarse, medium, fine, ultra-fine) for different finish requirements.

-

Delivers professional-grade finish on first pass: less rework, fewer operations.

-

Versatile tool: one wheel can serve cutting, smoothing, and finishing roles across different materials.

-

Better control: conformability means less operator dependence, more consistent results.

-

Safe for precision parts: reduced heat and minimal gouging protect part geometry and integrity.

-

Cost-effective: longer tool life and fewer changeovers reduce tooling cost.

-

Precision deburring and finishing of aerospace components and medical instruments.

-

Finishing of high-end decorative hardware, non-ferrous extrusions, and chromium parts.

-

Polishing of formed or laser-cut metal parts where surface appearance and quality matter.

-

Finishing of curved or irregular profiles where standard abrasives struggle to maintain full contact.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Industrial Brush |

| Material | Non Woven Abrasive |

| Packaging Type | Carton Box |

| Application | Deburring And Cleaning Metals |

| Size | 125mm to 200mm |

| Brand | Valgro |

| Maximum Speed | 3000 RPM |

The Valgro Turbine Disc Brush is a high-performance deburring tool engineered for medium and heavy-duty finishing applications. Its innovative turbine-style design, combined with silicon carbide and ceramic abrasive filaments, ensures aggressive cutting action, extended lifespan, and consistent edge finishing. This brush maintains its shape even under heavy use, delivering reliable and repeatable results in demanding production environments.

Overview

Built for precision and endurance, the Turbine Disc Brush is ideal for removing heavy burrs, rounding sharp edges, and cleaning surfaces with uniform results. Its stable construction prevents spreading or distortion, ensuring precise control and consistent material removal across each part. Designed for CNC machines, robotic finishing systems, and manual setups, it’s a versatile choice for metal fabricators seeking efficiency and accuracy.

Key Features

High-density fill with silicon carbide and ceramic filaments for aggressive performance.

Available in multiple grit sizes (60, 80, 120, 180) and diameters (125 mm, 150 mm, 200 mm).

Maintains brush shape during operation for consistent, predictable finishing.

Compatible with CNC centers, robotic arms, and automated finishing lines.

Long-lasting construction ensures reduced tool change frequency and downtime.

Benefits

Removes heavy burrs and sharp edges efficiently in fewer passes.

Produces smooth, consistent edge radii with controlled surface finish.

Reduces rework and manual finishing efforts, saving labor and cost.

Provides stable performance across high-volume production environments.

Improves product quality and surface preparation for downstream processes.

Typical Applications

Deburring and edge rounding of punched, stamped, or laser-cut sheet metal parts.

Surface preparation before coating, plating, or welding.

Suitable for heavy fabrication, appliance, and automotive metal components.

Ideal for automated production systems requiring precision and durability.

| Business Type | Manufacturer, Exporter, Supplier |

| Shape | Round |

| Type | Cleaning Brush |

| Material | Non Woven Abrasive |

| Brush Grade | CRS & MED |

| Usage | Disc Cleaning |

| Size | 300mm to 500mm |

| Brand | Valgro |

The Valgro Wide Face Disc Cleaning Brush is a high-performance abrasive disc assembly designed for large-format surface cleaning and preparation of metal strips and panels. It uses resin-bonded discs mounted on a robust core and features open-web construction to provide aggressive cleaning while maintaining workpiece flatness and geometry.

OverviewThis disc brush is specifically engineered to remove un-pickled patches, oxide films, oil spots, rust, mill-scale and other surface contamination from metal strips and panels prior to coating, finishing or further processing. Field trials indicate that using this cleaning brush can reduce chemical pickling costs by up to 70–75%.

Key Features-

Discs are resin-bonded together on a circular core for increased durability

-

Brush assembly built around a steel or FRP core to resist deflection under pressure

-

Abrasive minerals (aluminium-oxide or silicon-carbide) for sharp cutting action

-

Open-web construction resists loading and adapts to surface irregularities

-

Available in OD: 300 mm, 350 mm, 400 mm, 450 mm, 500 mm; width: 400 mm to 2500 mm; special sizes on request

-

Effectively removes corrosion, burrs, dirt and scale while preserving part geometry

-

Provides uniform and even surface finish with consistent roughness depth

-

Reduces pickling chemical usage and associated costs and environmental load

-

Enables improved coating adhesion due to superior cleaning and surface preparation

-

Suitable for high-throughput industrial operations with large format sheets and strips

-

Cleaning of steel, stainless steel, aluminium strips or coils prior to coating or finishing

-

Removal of oil patches, mill scale, rust and oxide films in strip processing or coil lines

-

Surface preparation for pre-coated sheet, architectural panels, industrial flooring and heavy fabrications

-

Integration in cleaning lines, brushing stations, coil-to-coil lines or sheet processing systems

| Business Type | Manufacturer, Exporter, Supplier |

| Shape | Round |

| Type | Finishing Brush |

| Material | Non Woven Abrasive |

| Color | Brown & Green |

| Application | Finishing or Polishing Metal |

| Size | 150mm to 500mm |

| Brand Name | Valgro |

The Valgro Wide Face Finishing Brush is a large-format non-woven abrasive roller brush designed for precision finishing of flat metal sheets and strips. It is built using Valgro’s durable non-woven “Valgro-Fynex” material, arranged in a flap construction for consistent surface finishing and long service life. This brush delivers uniform satin, matt, or hairline finishes on ferrous and non-ferrous metals.

OverviewEngineered for high-quality decorative and technical surface finishing, the Valgro Wide Face Finishing Brush ensures consistent geometry with minimal stock removal. It is suitable for both wet and dry operations and provides an even surface texture across large sheet widths.

Key Features-

Fully impregnated non-woven abrasive web for durability and long life.

-

Open-web structure for better airflow, reduced loading, and cooler operation.

-

Flexible and conformable design for uniform surface contact.

-

Available in a variety of diameters (150 mm–500 mm) and widths (400 mm–2500 mm).

-

Compatible with both wet and dry finishing systems.

-

Achieves uniform, high-quality finishes across wide surface areas.

-

Reduces rework and ensures consistent results in production.

-

Extends tool life and reduces overall finishing costs.

-

Minimizes heat build-up, preventing discoloration and distortion.

-

Ideal for high-throughput operations and large panel finishing.

-

Satin, matt, and hairline finishing of stainless steel sheets and panels.

-

Surface conditioning of aluminum, brass, and non-ferrous metals.

-

Large-area finishing for architectural, appliance, and industrial components.

-

Pre-finishing for coating, lamination, or polishing processes.