manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

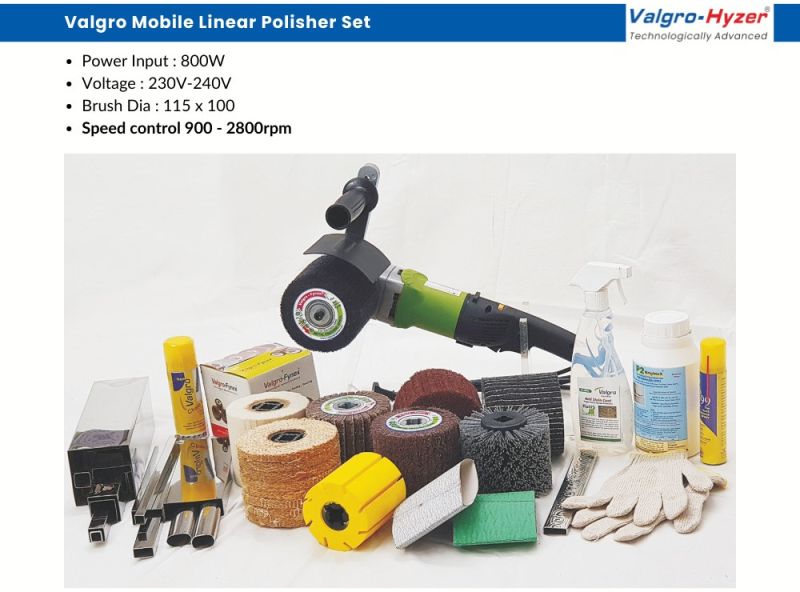

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 230V to 240V |

| Speed | 900 to 2800 RPM |

| Brush Diameter | 115 x 100mm |

| Click to view more | |

Product Details

Deliver professional-grade stainless-steel surface finishing with the Valgro SS Mobile Finishing Kit – Intro Pack 2. This complete mobile finishing kit is designed for fabrication shops seeking a full-scope on-site solution—covering everything from grinding to polishing and protective treatment—for stainless steel surfaces.

Overview

Built as an all-in-one finishing solution, this kit provides the tools and consumables needed to efficiently handle stainless steel finishing workflows: from weld-seam removal and scratch elimination to achieving satin, mirror, or decorative finishes, plus applying protective coatings. The mobile format ensures flexibility and portability, while offering comprehensive finishing capabilities.

Technical Specification:

- Rated Input Power: 800 W

- No-load Speed: 800–3000 RPM

- Spindle Diameter: 19mm

- Abrasive Tool Diameter: 115mm OD x 100mm Width x 19mm ID

- Weight (without power cable): 1.9 kg @

- Cable Length: 2 m / 6 ft @

- Noise Emission:

- Sound Pressure Level: 91 dB(A)

- Sound Power Level (LwA): 102 dB(A)

- Uncertainty of Measurement K: 3 dB (A)

Key Features

A powerful mobile linear polisher with variable speed control, engineered for consistent finishing across stainless steel surfaces

A full selection of abrasives: grinding belts, non-woven wheels, interleaved finishing wheels for satin or decorative finishes

High-quality finishing and polishing brushes and cloth wheels designed for mirror or near-mirror surfaces

Included surface treatment consumables: pickling/passivation gel to restore corrosion-resistance, anti-fingerprint coating for long-term finish integrity

Ergonomic and mobile design: the kit is intended for use directly at the job site, reducing material handling and enabling finishing in place

Benefits

Comprehensive: Delivers an end-to-end finishing solution rather than just a single tool, reducing the need for multiple separate purchases

Flexible: Supports a wide range of finish types—from functional satin finishes to high-gloss mirror finishes—depending on application requirements

Portable: Mobile kit format allows finishing to happen where the parts are rather than relocating parts to a central polishing station

Time-saving & cost-effective: Minimises logistics, handling and downtime, and reduces the need for external finishing services

Quality outcome: Ensures consistent surface appearance, high finish quality, and improved value for components or panels

Looking for "Valgro Stainless Steel Manual Finishing Full Kit" ?

Explore More Products