manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

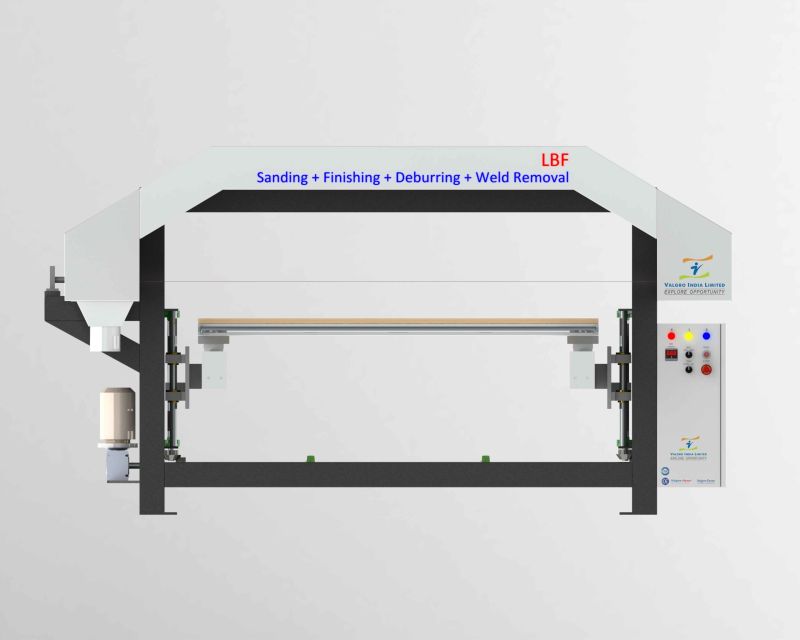

Long Belt Sander

Leading Manufacturers, Exporters and Wholesaler of Valgro LBF Automatic Metal Deburring Edge Rounding Work Station, Valgro LBF Economic Metal Deburring Edge Rounding Work Station and Valgro LBF Professional Metal Deburring Edge Rounding Work Station from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Metal Deburring Machine |

| Material | Mild Steel |

| Power Source | Electric |

| Brand | Valgro India |

| Usage | Deburring And Edge Rounding Metal Workpieces |

| Automation Grade | Automatic |

| Model | WS-50 Eco |

Valgro LBF Work Station – Automatic

The Valgro LBF Work Station – Automatic is a high-performance metal finishing machine designed for precise deburring, edge rounding, and surface finishing of sheet metal parts. It is ideal for industries requiring consistent and efficient processing of materials such as stainless steel, aluminum, and mild steel.

Key Features:

-

Versatile Processing: Capable of handling various metal parts, including those cut by punching, shearing, laser, or plasma.

-

Efficient Operation: Utilizes a long belt sander mechanism to remove burrs and round edges effectively.

-

Adjustable Settings: Offers adjustable conveyor speed and sanding pressure to accommodate different material types and thicknesses.

-

User-Friendly Interface: Equipped with an intuitive control panel for easy operation and monitoring.

-

Safety Features: Includes emergency stop buttons and safety guards to ensure operator safety during operation.

Applications:

-

Deburring: Effectively removes burrs from metal parts to ensure smooth edges.

-

Edge Rounding: Rounds sharp edges to prevent injuries and improve the aesthetic appearance of parts.

-

Surface Finishing: Enhances the surface quality of metal parts for a polished look.

Ideal For:

-

Industries requiring high-volume processing of metal parts.

-

Businesses seeking a reliable and efficient solution for metal finishing tasks.

-

Operations aiming to improve the quality and safety of their products through effective deburring and edge rounding

| Business Type | Manufacturer, Exporter, Supplier |

| Usage | Deburring And Edge Rounding of Matel |

| Brand | Valgro India |

| Power Source | Electric |

| Material | Mild Steel |

| Type | Work Station |

| Automation Grade | Semi Automatic |

| Model | WS-50 Eco |

Valgro LBF Work Station – Economic

The LBF Work Station – Economic is a compact, budget-friendly metal finishing solution tailored for small to medium-scale operations. It effectively handles deburring, edge rounding, and surface finishing tasks on sheet metal parts, ensuring a smooth and uniform finish.

Key Features:

-

Versatile Applications: Suitable for various metal parts, including those cut by punching, shearing, laser, or plasma.

-

Efficient Operation: Utilizes a long belt sander mechanism to remove burrs and round edges effectively.

-

Compact Design: Space-saving structure ideal for workshops with limited space.

-

User-Friendly Interface: Simplified controls for easy operation and maintenance.

-

Durable Construction: Built with high-quality materials to ensure longevity and reliability.

Applications:

-

Deburring: Removes sharp edges and burrs from metal parts.

-

Edge Rounding: Smooths edges to prevent injuries and improve aesthetics.

-

Surface Finishing: Enhances the surface quality of metal parts for a polished look.

Ideal For:

-

Small to medium-sized workshops.

-

Businesses seeking cost-effective metal finishing solutions.

-

Operations requiring efficient and reliable deburring and edge rounding capabilities.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Work Station |

| Material | Mild Steel |

| Power Source | Electric |

| Usage | Deburring And Edge Rounding |

| Brand | Valgro India |

| Model | WS 50 Pro |

| Voltage | 110-240V |

| Head Type | Bel Sander |

Valgro LBF Work Station – Professional

The Valgro LBF Work Station – Professional is a high-performance metal finishing machine designed for precision deburring, edge rounding, and surface finishing of sheet metal parts. It is ideal for industries requiring consistent and efficient processing of materials such as stainless steel, aluminum, and mild steel.

Key Features:

-

Versatile Processing: Capable of handling various metal parts, including those cut by punching, shearing, laser, or plasma.

-

Efficient Operation: Utilizes a long belt sander mechanism to remove burrs and round edges effectively.

-

Adjustable Settings: Offers adjustable conveyor speed and sanding pressure to accommodate different material types and thicknesses.

-

User-Friendly Interface: Equipped with an intuitive control panel for easy operation and monitoring.

-

Safety Features: Includes emergency stop buttons and safety guards to ensure operator safety during operation.

Applications:

-

Deburring: Effectively removes burrs from metal parts to ensure smooth edges.

-

Edge Rounding: Rounds sharp edges to prevent injuries and improve the aesthetic appearance of parts.

-

Surface Finishing: Enhances the surface quality of metal parts for a polished look.

Ideal For:

-

Industries requiring high-volume processing of metal parts.

-

Businesses seeking a reliable and efficient solution for metal finishing tasks.

-

Operations aiming to improve the quality and safety of their products through effective deburring and edge rounding.