manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

FRP Industrial Solutions

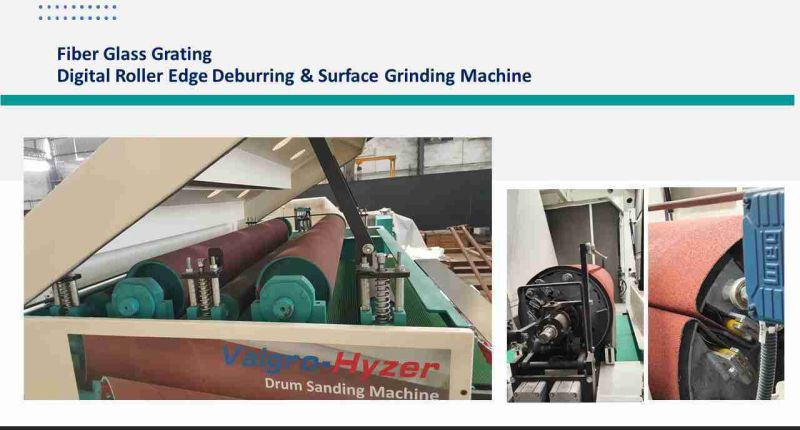

Leading Manufacturers, Exporters and Wholesaler of Valgro Advance Grating Grinding Machine, Valgro Grating Drum Sanding Machine, Valgro Grating Edge Deburring Machine, Valgro Gypsum Board Sanding Machine and Valgro Wet Brushing Hot Tempered Strip Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Automation Level | Semi Automatic |

| Type | Grinding Machine |

| Material Comptable | FRP Sheet |

| Usage | Grating And Grinding FRP Sheet |

| Power Source | Electric |

| Voltage | 420V |

| Frequency | 50-60Hz |

| Brand | Valgro |

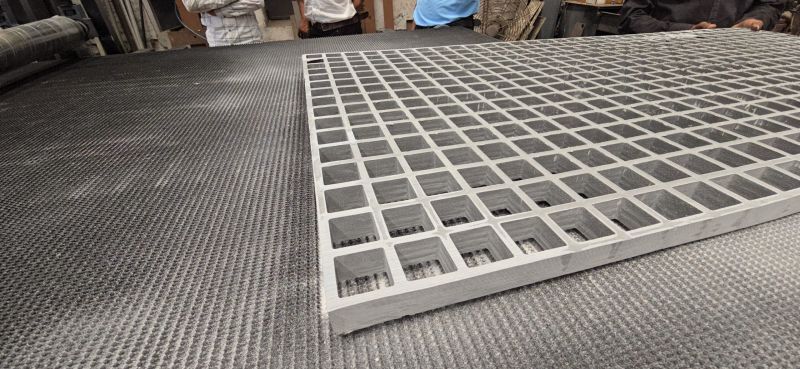

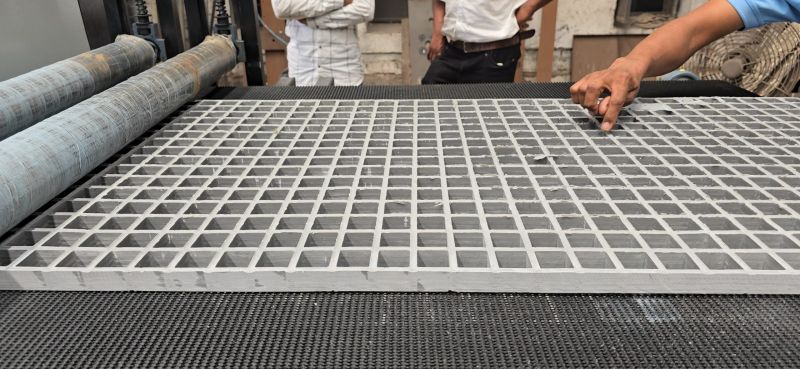

The Valgro Advance Grating Grinding Machine is designed for fast and precise surface preparation of FRP gratings, ceramic boards, gypsum panels, and cement sheets. It delivers uniform, high-quality finishes with remarkable efficiency — completing one full grating panel in just about 30 seconds.

OverviewThis heavy-duty wide-belt sanding system is engineered to handle large-format materials with ease. Equipped with open-coated, coarse-gritted resin-fiber belts, it ensures smooth, even finishes while maintaining low power consumption and high throughput. Ideal for both industrial and construction material processing, it guarantees consistent results and improved productivity.

Key Features-

Finishes a full FRP grating panel in approximately 30 seconds

-

Uses open-coated, coarse-grit resin-fiber abrasive belts for superior surface quality

-

Wide-belt abrasive system ensures uniform finishing across large panels

-

Adjustable grinding pressure and feed rate for precise control

-

Integrated dust extraction system keeps the workspace clean

-

Suitable for FRP, ceramic, gypsum, and cement-based materials

-

Reduces finishing cycle time and manual labor

-

Provides smoother and safer surface edges

-

Enhances product durability and corrosion resistance

-

Optimizes energy use for cost-effective operation

-

Ensures consistent finish quality in high-volume production

-

Edge and surface finishing of FRP (Fibre-Reinforced Plastic) gratings

-

Grinding of ceramic, gypsum, and cement boards

-

Pre-finishing panels used in construction, flooring, and industrial walkways

-

Ideal for manufacturers and processors requiring fast, consistent panel preparation

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi Automatic |

| Type | Sanding Machines |

| Brand Name | Valgro |

| Material Comptable | FRP |

| Drum Diameter | 200mm |

| Application | Sanding FRP Panels |

| Power Source | Electric |

The Valgro Grating Drum Sanding Machine is designed for efficient surface finishing of grating panels and large-format workpieces. It offers an economical yet durable solution for industrial operations that demand high productivity and uniform sanding results.

OverviewThis machine uses a single hardened steel drum (approximately 180 mm in diameter) to sand and finish grating panels quickly and evenly. With a continuous conveyor feed, it enables smooth and consistent processing of panels, significantly reducing manual labor and processing time.

Key Features-

Hardened steel drum (~180 mm diameter) for long-lasting durability and efficient sanding

-

Abrasive belt drum system allows quick and easy belt replacement, minimizing downtime

-

Heavy-duty auto-feed conveyor ensures smooth and steady workpiece movement

-

Cost-effective design providing industrial performance at a lower investment

-

Ideal for grating and large sheet panels where open edges, rough surfaces, or fibre exposure need finishing

-

High throughput: Enables rapid sanding cycles, improving production efficiency

-

Cost-effective: Provides robust performance without the high cost of complex finishing systems

-

Easy maintenance: Simple design and quick belt-change mechanism reduce downtime

-

Improved surface quality: Produces uniform, smooth surfaces and eliminates sharp edges for safer handling and better coating adhesion

-

Finishing of FRP (Fibre-Reinforced Plastic) gratings — removing rough edges and exposed fibres

-

Surface preparation of metal and composite panels before coating or assembly

-

Ideal for fabricators, grating manufacturers, and sheet processing workshops requiring a mid-volume, high-efficiency sanding system

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Valgro |

| Material Comptable | FRP Panel and Metal Grating |

| Application | Deburring Edges Of Gratings |

| Power Source | Electric |

| Voltage | 420V |

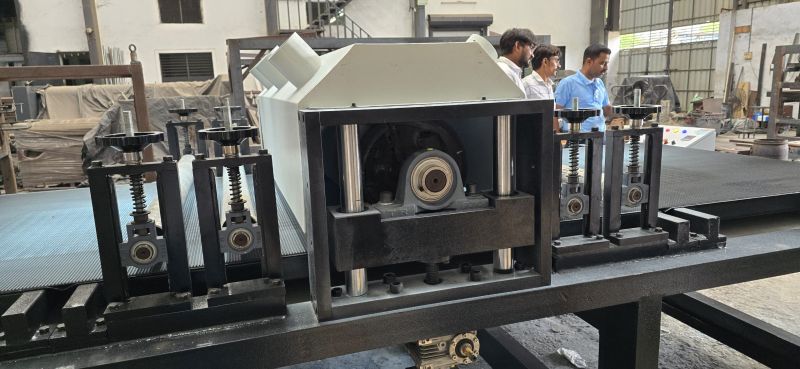

| Panel Length | 2500mm |

| Panel Width | 1250mm |

| Thickness | 75mm |

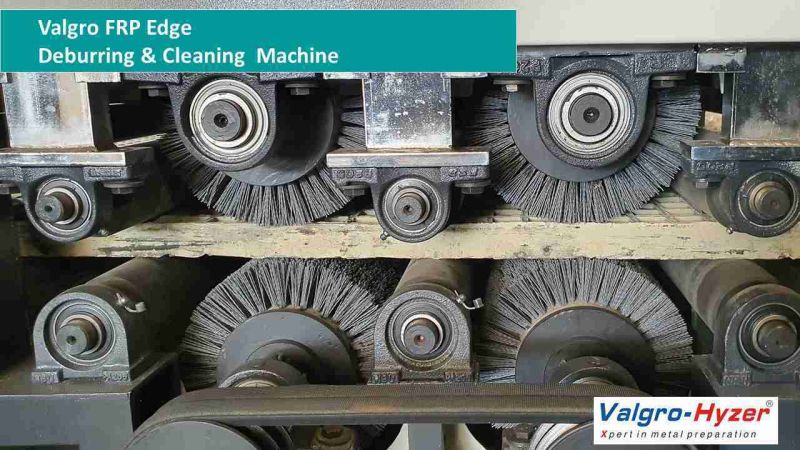

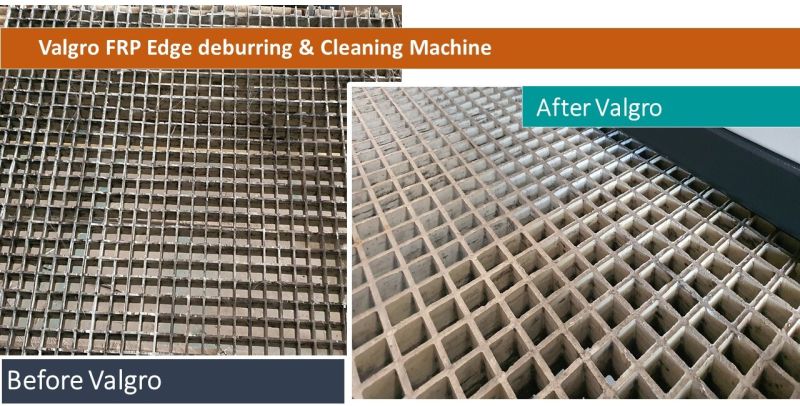

The Valgro Grating Edge Deburring Machine is engineered for efficient and reliable removal of burrs and rough edges on grating panels — whether FRP (fibre-reinforced plastic) or metal. Designed to deliver uniform, safe, and finished edges, this machine ensures panels meet quality, appearance and safety standards.

OverviewGrating panels often emerge from cutting or fabrication processes with sharp edges, exposed fibres or unfinished surfaces which can impair durability or increase risk of injury. The Valgro Grating Edge Deburring Machine addresses these challenges by providing a dedicated edge-finishing solution capable of smoothing, rounding and cleaning panel edges with speed and consistency. The system is built to integrate into production lines for high-volume output while maintaining precision.

Key Features-

Specialized for edge finishing of grating panels (metal or FRP) to remove burrs, exposed fibres and sharp edges

-

Robust construction suited for industrial use and continuous operation

-

Uniform edge treatment for improved safety (no sharp edges) and improved downstream performance (coating, installation)

-

Suitable for high throughput: designed to handle panel feed, edge deburring and cleaning in an efficient workflow

-

Improves panel finish quality and supports better edge integrity / fibre containment in FRP or better edge condition in metal grating

-

Enhances product safety and reduces risk of injury from sharp or unfinished edges

-

Improves aesthetics and finishing quality – smoother edges, fewer defects

-

Reduces labour cost and time compared to manual edge finishing methods

-

Supports coating, installation, or assembly by delivering panels with ready-finished edges

-

Gives better durability (especially for FRP gratings) by limiting exposed fibres or poorly finished edges

-

Deburring and edge finishing of FRP gratings used in flooring, platforms, walkways or industrial sections

-

Finishing metal grating panels or architectural grating panels where edges must be smooth and safe

-

Fabrication lines where grating panels are produced at scale and require consistent edge finish for installation or coating

-

Construction, marine, petrochemical, industrial flooring sectors where grating safety and finish matter

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Sanding Machine |

| Material Comptable | Gypsum Board |

| Application | Gypsum Board Sanding |

| Brand Name | Valgro |

| Power Source | Electric |

| Voltage | 110-240V |

| Speed | 960 Mile Per Minutes |

| Head Diameter | 130mm |

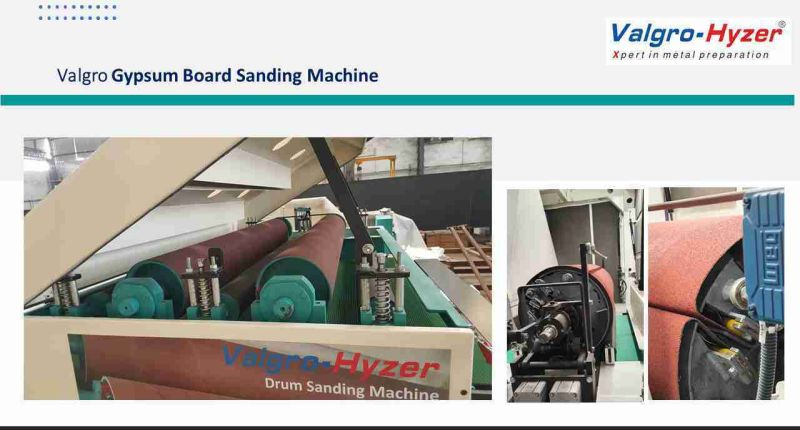

Transform your gypsum board surface preparation process with the Valgro Gypsum Board Sanding Machine — built to deliver smooth, uniform sanding of gypsum wallboard surfaces, ready for paint or coverings. The machine ensures consistent surface quality while preserving board integrity and minimizing sound-absorption defects.

OverviewThe machine features a dual drum-head sanding setup: the first drum handles rough sanding, while the second drum provides fine finishing. It uses a hardened steel roller head (approximately 130 mm in diameter) with an abrasion-resistant rubber coating, operating at around 960 rpm. The system supports boards up to 1250 mm in width, 2500 mm in length, and 100 mm in thickness, with an adjustable conveyor speed ranging from 0.5 to 10 m/min.

Key Features-

Dual drum sanding heads for rough and fine finishing

-

Hardened steel roller head (~130 mm diameter) with durable rubber coating

-

High-speed sanding head operation (~960 rpm)

-

Adjustable conveyor speed (0.5–10 m/min) for flexibility

-

Supports maximum working width of 1250 mm, length of 2500 mm, and thickness up to 100 mm

-

Delivers a soft, bright, and uniform surface finish

-

Reduces sound absorption defects on gypsum boards

-

Provides consistent, high-quality sanding across the entire board

-

Prepares boards perfectly for painting or surface covering

-

Eliminates surface imperfections and texture irregularities

-

Adjustable settings for different board sizes and materials

-

Robust industrial construction for long-term reliability

-

Sanding of gypsum wallboards used in interiors, ceilings, and partitions

-

Preparation of boards for surface finishing (painting, laminating, coating)

-

Ideal for drywall and gypsum board manufacturing facilities

-

Suitable for construction material plants prioritizing surface quality

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi Automatic |

| Type | Grinding Machine |

| Material Comptable | Stainless Steel |

| Application | Wet Brushing |

| Power Source | Electric |

| Noise Level | Less then 80DB |

| Brand | Valgro |

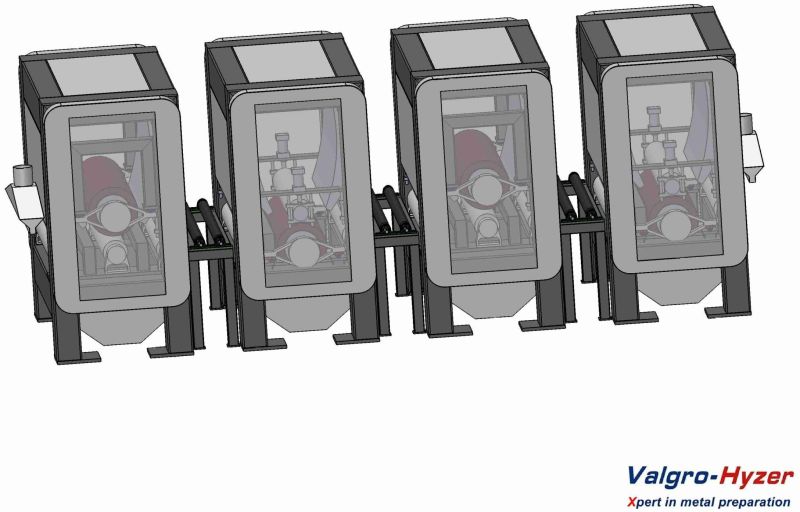

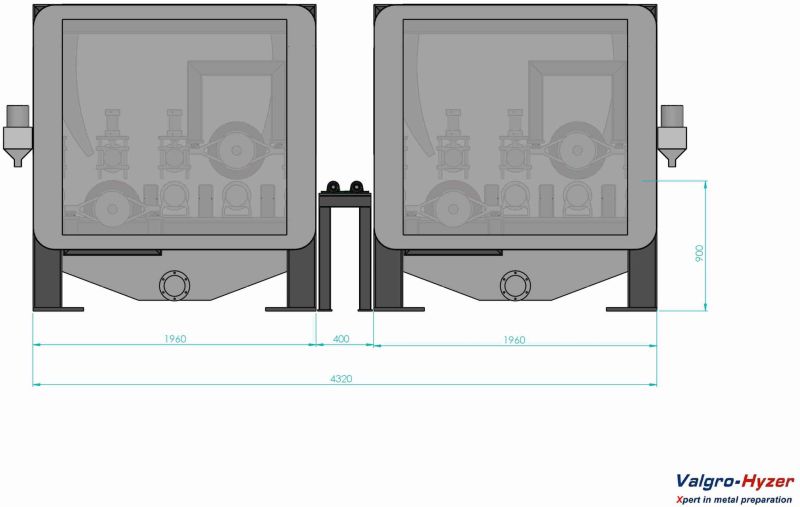

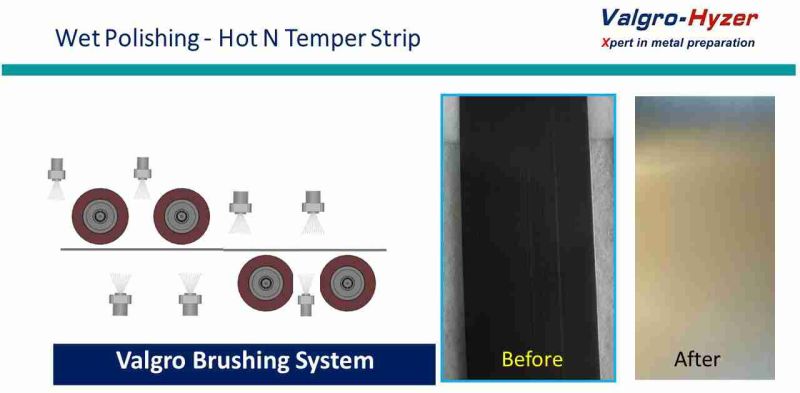

Improve the surface quality of hardened and tempered steel strips with the Valgro Wet Brushing Hard & Tempered Strip Machine — a dedicated wet-brushing solution designed for strip finishing where tight flatness and minimal material removal are required.

OverviewThis wet-brushing machine uses rotating abrasive brushes under coolant to uniformly remove a thin layer (approximately 1-2 µm) from hardened or tempered steel strips. It’s designed to reduce surface roughness (from approx Ra 1.15 µm incoming down to Ra 0.12 µm) and remove loose scale, micro-irregularities or surface contamination, while preserving flatness (no camber or deformation). It includes a sealed brushing chamber with inspection windows for process monitoring.

Key Features-

Designed for wet brushing of hardened/tempered strips, utilising coolant to manage heat and clean sweeping.

-

Removes approx 1-2 µm of material to deliver a refined surface with low roughness (target Ra ≈ 0.12 µm).

-

Vibration-free and stable operation with guarantee of no strip deformation or camber.

-

Sealed machine housing with viewing windows for operator visibility.

-

Low noise operation (< 80 dB) and power-efficient performance.

-

Robust, heavy-duty construction built for continuous industrial strip processing.

-

Consistently delivers high-quality strip surfaces with improved flatness and finish quality.

-

Helps downstream processes (coating, cladding, bonding) by providing a better base surface condition.

-

Wet process improves tool life and process cleanliness compared to dry brushing in certain contexts.

-

Reduces operational defects such as strip camber or handling issues due to improved flatness.

-

Suitable for high-volume industrial lines where reliability and repeatable results are essential.

-

Surface preparation of hardened or tempered steel strips used in cladding, coating, bonding or roll-processing.

-

Strip finishing where removal of light scale, annealing colours or micro defects is required before further processing.

-

Heavy industrial strip lines where maintaining flatness and surface uniformity is critical (automotive, heavy fabrication, bearing strips, high-precision components).

-

Facilities preferring wet brushing due to cooling, material condition or process-integration advantages.