manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

Fabrication Shop Finishing Solution

Leading Manufacturers, Exporters and Wholesaler of Valgro Stainless Steel Manual Finishing Full Kit, Valgro Stainless Steel Mobile Finishing Kit and Valgro Three Tiger Mobile Polisher Kit from Ahmedabad.

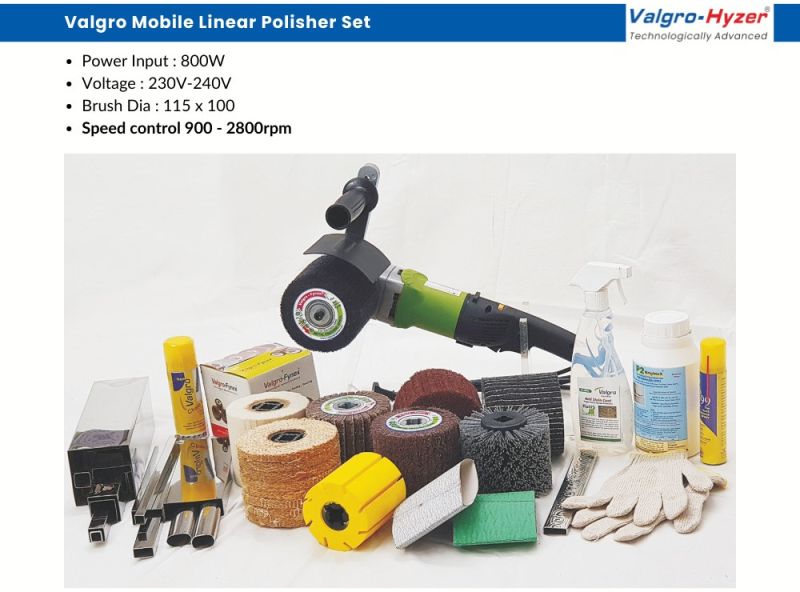

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 230V to 240V |

| Speed | 900 to 2800 RPM |

| Brush Diameter | 115 x 100mm |

| Type | Finishing Kit |

| Material Comptable | Stainless Steel |

| Power | 800 Watt |

| Application | Finishing Metal Sheet |

| Brand Name | Valgro |

Deliver professional-grade stainless-steel surface finishing with the Valgro SS Mobile Finishing Kit – Intro Pack 2. This complete mobile finishing kit is designed for fabrication shops seeking a full-scope on-site solution—covering everything from grinding to polishing and protective treatment—for stainless steel surfaces.

Overview

Built as an all-in-one finishing solution, this kit provides the tools and consumables needed to efficiently handle stainless steel finishing workflows: from weld-seam removal and scratch elimination to achieving satin, mirror, or decorative finishes, plus applying protective coatings. The mobile format ensures flexibility and portability, while offering comprehensive finishing capabilities.

Technical Specification:

- Rated Input Power: 800 W

- No-load Speed: 800–3000 RPM

- Spindle Diameter: 19mm

- Abrasive Tool Diameter: 115mm OD x 100mm Width x 19mm ID

- Weight (without power cable): 1.9 kg @

- Cable Length: 2 m / 6 ft @

- Noise Emission:

- Sound Pressure Level: 91 dB(A)

- Sound Power Level (LwA): 102 dB(A)

- Uncertainty of Measurement K: 3 dB (A)

Key Features

A powerful mobile linear polisher with variable speed control, engineered for consistent finishing across stainless steel surfaces

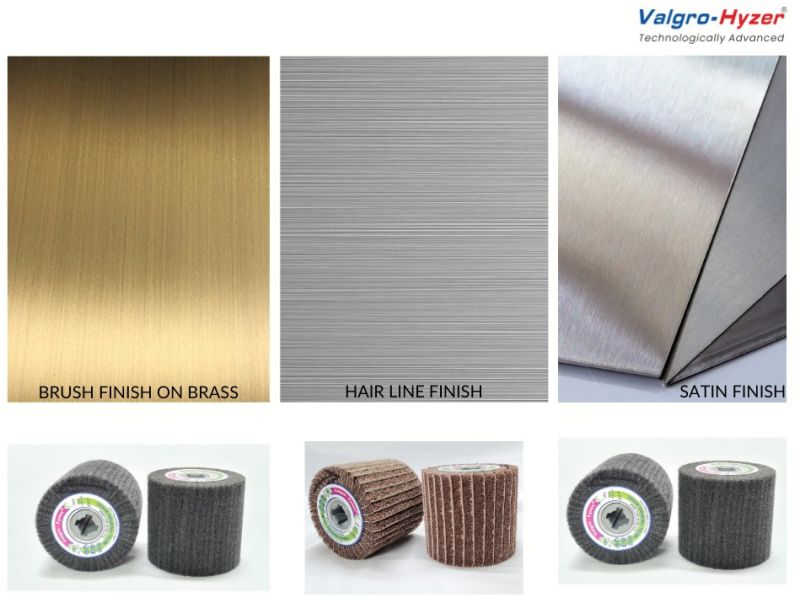

A full selection of abrasives: grinding belts, non-woven wheels, interleaved finishing wheels for satin or decorative finishes

High-quality finishing and polishing brushes and cloth wheels designed for mirror or near-mirror surfaces

Included surface treatment consumables: pickling/passivation gel to restore corrosion-resistance, anti-fingerprint coating for long-term finish integrity

Ergonomic and mobile design: the kit is intended for use directly at the job site, reducing material handling and enabling finishing in place

Benefits

Comprehensive: Delivers an end-to-end finishing solution rather than just a single tool, reducing the need for multiple separate purchases

Flexible: Supports a wide range of finish types—from functional satin finishes to high-gloss mirror finishes—depending on application requirements

Portable: Mobile kit format allows finishing to happen where the parts are rather than relocating parts to a central polishing station

Time-saving & cost-effective: Minimises logistics, handling and downtime, and reduces the need for external finishing services

Quality outcome: Ensures consistent surface appearance, high finish quality, and improved value for components or panels

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Power | 800 Watt |

| Type | Finishing Kit |

| Material Comptable | Stainless Steel |

| Operation Type | Manual |

| Application | Finishing Metal Surfaces |

| Brand Name | Valgro |

Elevate your stainless-steel finishing process with the Valgro SS Mobile Finishing Kit – Intro Pack 1. This mobile finishing kit is thoughtfully designed for sheet metal fabrication shops, providing a compact, on-site solution for achieving professional surface finishes on stainless steel. Ideal for small to medium fabrication applications, it delivers streak-free, shadow-free finishes with minimal effort.

OverviewThe kit enables you to clean, refine and finish stainless steel surfaces — removing dirt, weld seams, scratches and tarnish — then applying your choice of finish: satin, matte, hairline or grain. The mobile nature of the kit enables finishing directly at the work site, reducing handling and downtime.

Technical Specification:

- Mobile Linear Polisher 800 Watt with Variable speed control, = 1 No.

- High-quality abrasion-resistant rubber drum = 1 no.

- Scratch Grinding Abrasive Belt 80 Grit = 5 No.

- Scratch Grinding Abrasive Belt 120 Grit = 5 No.

- Valgro Finishing Wheel = 115 x 100mm PCRS = 01 No.

- Valgro Finishing Wheel = 115 x 100mm PFN = 01 No.

- Manual For finishing Recipe

-

Mobile linear polisher (800 W) with variable speed control for versatility in finishing different surfaces.

-

Abrasive grinding belts (80 grit, 120 grit) for efficient scratch removal and surface refinement.

-

High-quality rubber drum for consistent pressure and uniform surface treatment.

-

Finishing brushes (115 × 100 mm) for smooth blending and achieving a flawless streak-free matte finish.

-

Manual with finishing “recipe” included to guide the user through steps for consistent results.

-

On-site finishing: The mobile kit enables finishing of stainless steel sheets, panels or components without relocating them to a central polishing machine.

-

Cost-effective: Ideal for smaller operations or job-site finishing where a full-sized polishing line is impractical.

-

Versatile finishes: From satin and matte to hairline and grain finishes, the kit supports multiple finish types.

-

Improved productivity: Reduces handling, travel of materials, and allows finishing right where the work is — saving time and labour.

-

Stainless steel sheet fabrication for kitchen equipment, restaurant appliances, dairy or food-processing machinery.

-

Elevator doors, escalator panels, architectural stainless steel cladding and handrails.

-

Ship-building, rail/metro components, and other metal-fabrication jobs requiring onsite finishing.

-

Any job-shop or fabrication environment that requires professional-grade surface finishes but cannot justify full-size finishing lines.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polisher Kit |

| Application | Metal Sheet Polishing |

| Included Items | Three Tiger Mobile Polisher, Polishing Pads, Power Adapter |

| Brand | Valgro |

| Power | 800W |

| Speed | 800 to 3000 RPM |

| Cable Length | 1.9 m |

| Power Source | Electric |

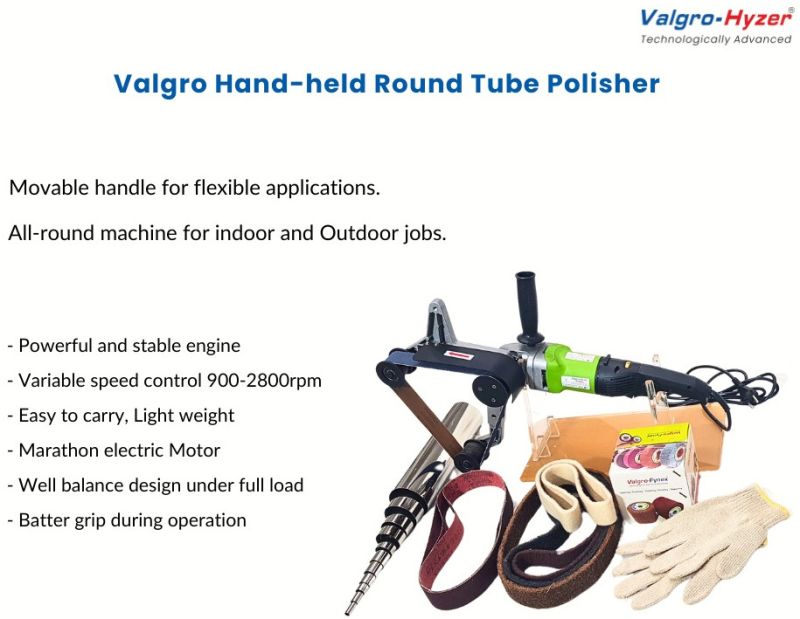

Elevate your stainless steel fabrication finishing operations with the Valgro Three Tiger Mobile Polisher Kit — a comprehensive, mobile finishing solution designed for fabrication shops seeking flexibility, portability, and superior surface quality.

OverviewThis kit combines three specialized handheld polishing tools to cover virtually all finishing needs:

-

A mobile linear polisher for flat surfaces

-

A mobile round-tube polisher for pipes and profiles

-

An easy-corner polisher for welds, inside corners, and hard-to-reach areas

These tools come with the required accessories, enabling you to achieve professional-grade finishes on-site without relocating workpieces to central polishing machines.

Key Features-

Three-in-one kit:

-

Linear Polisher – for sheet metal, panels, and flat surfaces

-

Round Tube Polisher – for tubes, handrails, and curved profiles

-

Corner Polisher – for polishing inside corners, weld seams, and narrow spaces

-

-

Portable, ergonomic handheld design with high-performance motors for workshop or on-site use

-

Variable speed control for precision finishing across different surface types

-

Supports multiple finish types including satin, hairline, matte, grain, and mirror finishes

-

Removes weld seams, scratches, oxidation, and tarnish, leaving a smooth, uniform finish

-

On-site mobility: Enables finishing directly at the fabrication area, reducing handling and downtime

-

Versatility: Covers flat, curved, and corner surfaces — one kit for complete stainless steel finishing

-

Enhanced productivity: Faster turnaround and simplified tool management

-

Professional results: Delivers high-quality, consistent finishes suitable for architectural and industrial applications

-

Cost-effective: Eliminates the need for multiple dedicated polishing machines

-

Stainless steel fabrication for kitchen equipment, food-processing, and pharmaceutical machinery

-

Architectural stainless steel features such as handrails, elevator interiors, and decorative cladding

-

On-site finishing in construction, rail, or shipbuilding where portability is essential

-

General stainless steel workshops handling varied finishing jobs on different part geometries