manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

Fabrica Polishing Machine

Leading Manufacturers, Exporters and Wholesaler of Valgro Aluminium Profile Brushing Machine, Valgro Aluminium Profile High Gloss Polishing Machine, Valgro Aluminium Sheet Polishing Machine, Valgro Bend Oval Tube Polishing Machine, Valgro Busbar Deburring Polishing Machine, Valgro Round Tube Polishing Machine, Valgro Square Rectangle Tube Polishing Machine, Valgro Stainless Steel Sheet Polishing Machine and Valgro Strip Coil Polishing Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Brush Diameter | 300mm |

| Type | Brushing Machine |

| Material Comptable | Aluminium |

| Model | AL06-2 |

| Head Type | Roller Brush |

| Application | Profile Brushing |

| Brand Name | Valgro India |

Product Description:

The Valgro Aluminium Profile Brushing Machine is designed for precision surface finishing of aluminium extrusion profiles, providing high-quality matt, hairline, and brush finishes. It effectively removes extrusion marks, scratches, and handling defects, ensuring a uniform grain pattern. Built for dry operation, the machine minimizes dust, power use, and maintenance, while reducing downstream etching and chemical costs.

Key Features & Benefits:

-

Plug-and-play design, easy to operate even by unskilled labour

-

Vertical axis rotating and oscillating brush heads for even finish

-

Adjustable brushing pressure with user-friendly control panel

-

Delivers uniform finish with minimal dust and heat generation

-

Reduces the need for polishing paste and chemical pre-treatment

-

Compact, rust-resistant structure with low power consumption

-

Consistent surface finish suitable for architectural-grade results

Applications:

-

Aluminium profiles for doors, windows, furniture, and facades

-

Decorative and architectural aluminium finishing

-

Pre-treatment before anodising, powder coating, or electro-finishing

Technical Summary:

-

Model Range: ALU-Series (e.g., ALU14-4 TNB)

-

Finish Achieved: Matt, Hairline, Brush Grain

-

Process Type: Dry Operation (optional wet process available)

-

Material Compatibility: Aluminium profiles and extrusions

-

Profile Width: Up to 150 mm

-

Profile Thickness: 0.8 mm to 3 mm

-

Brand: Valgro

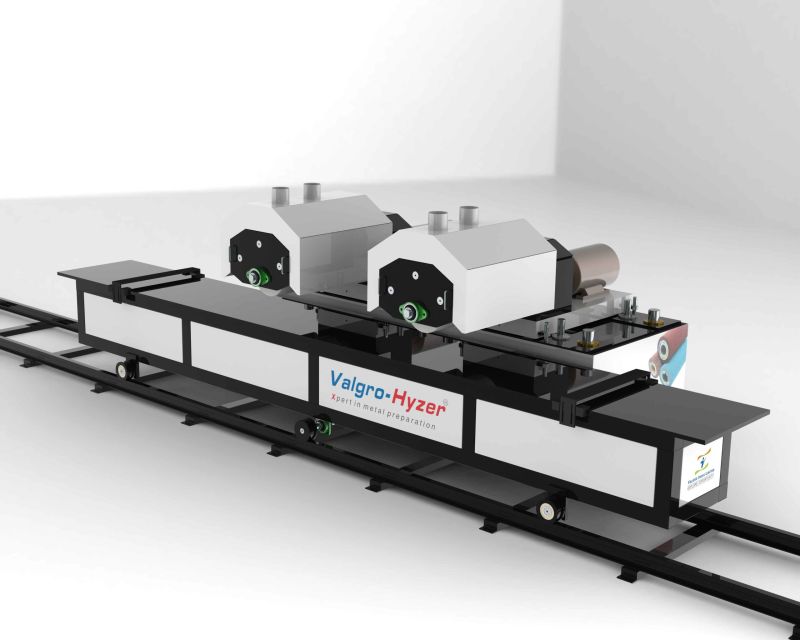

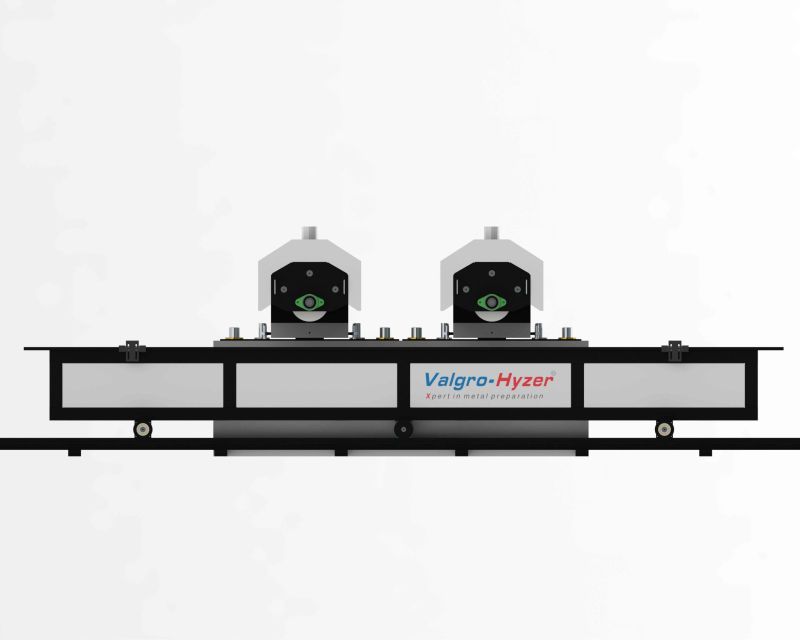

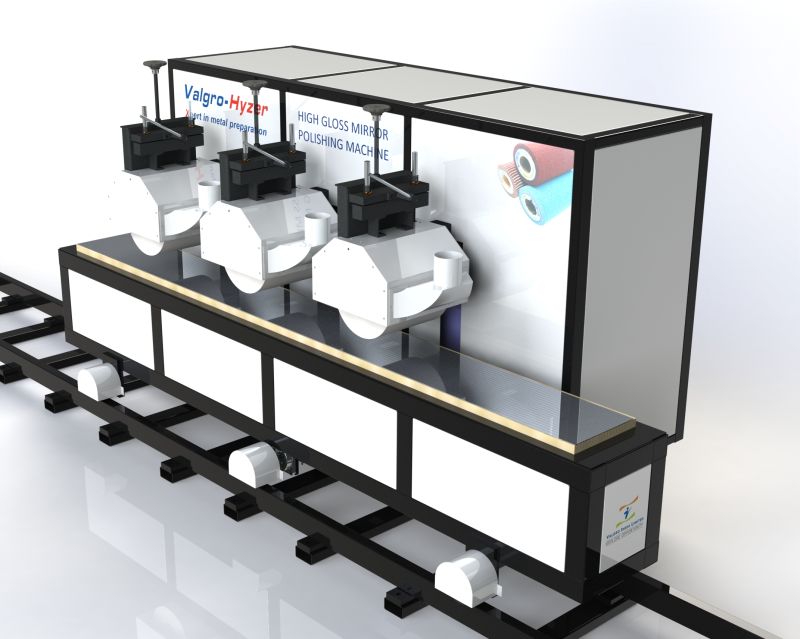

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Head Type | Roller Brush |

| Type | Polishing Machine |

| Material Comptable | Aluminium |

| Finish | High Gloss Mirror |

| Model | AL 12-2G |

| Application | Polishing The Aluminium Sheet |

| Brand Name | Valgro India |

Product Description:

The Valgro Aluminium Profile High Gloss Polishing Machine is designed to deliver mirror-like, high-gloss finishes on aluminium extrusion profiles. It efficiently removes oxidation film, extrusion lines, and surface imperfections to produce a flawless reflective finish. Built with a sturdy design and low-vibration mechanism, it ensures consistent, noiseless, and heat-free operation for long-lasting performance.

Key Features & Benefits:

-

Produces mirror-grade, high-gloss finish on aluminium profiles

-

Sturdy construction ensures stability and durability during operation

-

Minimal heat and noise generation for safe, clean working

-

Ideal for anodised, bright oxidised, or nickel-plated aluminium surfaces

-

Reduces polishing time while enhancing surface brilliance and appeal

-

Low maintenance and energy-efficient performance

Applications:

-

Architectural aluminium profiles for windows, doors, and facades

-

Decorative and designer aluminium furniture elements

-

Pre-treatment before anodising or electro-finishing

-

Bright polishing for consumer and industrial aluminium products

Technical Summary:

-

Model: High Gloss Polishing Machine for Aluminium Profiles

-

Finish Type: Mirror / High Gloss

-

Process Type: Dry Mechanical Polishing

-

Material Compatibility: Aluminium extrusion profiles (anodised, oxidised, coated)

-

Operation: Smooth, low-noise, low-vibration system

-

Brand: Valgro

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Type | Sheet Polishing Machine |

| Usage | Polishing Sheets Efficiently |

| Brand Name | Valgro India |

| Brush Diameter | 125mm |

| Automation Grade | Fully Automatic |

| Sheet Material | Aluminium |

| Model | DB-24 HD |

Product Description:

The Valgro Aluminium Sheet Polishing Machine is a high-performance finishing solution designed to produce fine mechanical finishes such as satin, brush, or hairline on aluminium sheets before anodising. It removes scratches, marks, and surface impurities using precision abrasive brushes, ensuring smooth, uniform surfaces and consistent preparation for further coating or finishing. The machine helps reduce chemical etching time, minimize water usage, and lower overall production costs, while maintaining excellent surface quality.

Key Features & Benefits:

-

Suitable for aluminium sheets from 0.8 mm to 3 mm thickness

-

Dry-process operation — clean, eco-friendly, and low maintenance

-

Compact design ideal for in-house finishing applications

-

Delivers uniform brush, matt, satin, or hairline finishes

-

Reduces manual labour, handling time, and surface defects

-

Enhances pre-anodising preparation and coating performance

-

Ensures consistent, professional-grade polishing results

Applications:

-

Aluminium architectural panel and signboard finishing

-

Aerospace and automotive component manufacturing

-

Bus body and vehicle fabrication

-

Industrial and decorative aluminium processing

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Tube Polishing Machine |

| Material Comptable | Stainless Steel , Brass, Copper and Aluminium |

| Head Type | Planetary Head Adrasive Belt |

| Brand Name | Valgro |

| Model | BTP-25 |

| Power Source | Electric |

| Finish Achieved | Hairline |

Product Description:

The Valgro Bend & Oval Tube Polishing Machine is a sophisticated finishing system engineered to treat straight, curved, oval and bent tubes without rotating them. Its planetary head mechanism allows the abrasive belts to rotate around the tube, delivering even, high-quality surface finishes with minimal vibration, lower heat generation and reduced operator strain.

Key Features & Benefits:

-

Planetary head system: polishing without tube rotation

-

Handles straight and bent tubes, oval or irregular shapes

-

Minimal vibration, even for long tube lengths

-

Gentle belt contact reduces heat and protects material

-

Quick abrasive belt changes for higher uptime

-

Improved operator safety: less dust, less noise, no flying sparks

-

Suitable for unskilled labor, saving training time and cost

Applications:

-

Finishing of bend, oval and elliptical tubes in architectural and furniture fabrication

-

Automotive and transport tube fabrication

-

Decorative metal work tubes, railings and balustrades

-

Manufacturing of curved structural tubes and profiles

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polishing Machine |

| Material | Mild Steel |

| Model | HYB 06 |

| Brand Name | Valgro India |

| Application | Deburring And Polishing Busbars |

| Power Source | Electric |

| Brush Diameter | 300mm |

| Material Compatibility | Copper and Aluminium bus bars |

| Driven Type | Electric |

Product Description:

The Valgro Busbar Deburring & Polishing Machine offers a streamlined solution for preparing copper and aluminium bus bars with burr-free, high-conductivity surfaces. This machine removes oxidation, tarnish and surface imperfections to deliver smooth, finished bus bars that reduce electrical resistance and energy loss in power distribution systems.

Key Features & Benefits:

-

Removes burrs and oxidation from punching, stamping and fabrication edges

-

Ensures smooth, clean surfaces for optimal electrical conductivity

-

Enhances corrosion resistance and extends the service life of bus bars

-

Delivers consistent, high-precision finishing across multiple units

-

User-friendly interface with automation options for productivity

-

Promotes energy efficiency and cost savings by reducing power losses

-

Suits industrial settings with demanding electrical and quality standards

Applications:

-

Electrical manufacturing: switchgear, control panels and bus bar assemblies

-

Renewable energy: solar, wind and battery systems needing high-efficiency power transmission

-

Industrial electrical distribution and panel building

-

Bus bar fabrication for infrastructure, utilities and heavy-engineering sectors

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Tube Polishing Machine |

| Model | RTP01-3 |

| Head Type | Planetary Head Adrasive Belt |

| Work Surface | Round Surface |

| Application | Polishing Round Tubes |

| Brand Name | Valgro India |

| Material Compatibility | Stainless Steel, Brass & Aluminium |

| Power Source | Electric |

Product Description:

The Valgro Round Tube Polishing Machine – Planetary Head is a high-performance finishing solution designed for polishing straight, bent, round, oval and curved tubes without rotating the workpiece. The planetary system allows the abrasive belts to rotate around the tube, providing smooth, uniform surface finishes with minimal vibration or heat. Ideal for stainless steel, aluminium, brass and copper tubes of varying diameters, it supports both straight and bent parts, reducing labour strain, improving safety and enhancing productivity.

Key Features & Benefits:

-

Planetary head design: no tube rotation during polishing

-

Suitable for straight or curved tubes (round, oval, bent)

-

Low vibration even on long tube lengths

-

Quick abrasive belt changes and easily maintainable

-

Soft contact on tube surface ensures minimal heat

-

Manual feed or optional automatic feeding system

-

Compatible with Stainless Steel, Aluminium, Brass, Copper

Applications:

-

Round and oval tube fabrication for architecture and furniture

-

Automotive, transport and body-fabrication components

-

Metal finishing for railing, handrail, balustrade tubes

-

Manufacturing of decorative tubes, structural tubes in construction

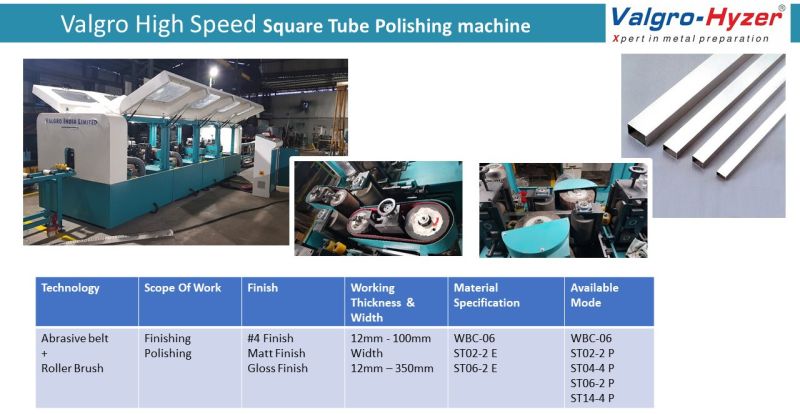

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polishing Machine |

| Tube Shape | Square & Rectangle Tube |

| Brand Name | Valgro |

| Model | HYB 06 |

| Head Type | Belt and Roller Brush |

| Brush Diameter | 225mm |

| Application | Metal Polishing |

| Power Source | Electric |

Product Description:

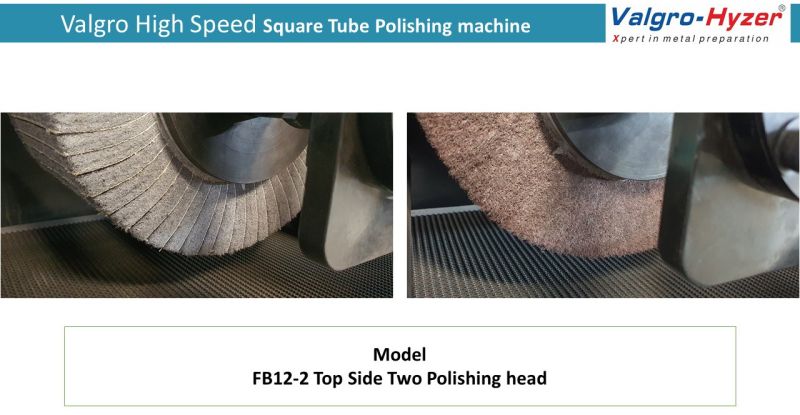

The Valgro Square & Rectangle Tube Polishing Machine is built specifically for surface finishing of square and rectangular tubes. Engineered with twin-head abrasive belt technology and conveyorised feed, it delivers uniform matt, satin, hairline or high-gloss finishes without distortion. This machine enables efficient in-house polishing, reduces handling and power consumption, and supports both wet and dry process variants.

Key Features & Benefits:

-

Twin-head belt + roller brush system for high productivity

-

Handles square/rectangular tube profiles with minimal distortion

-

Excellent finish types: matt, satin, hairline, gloss mirror

-

Oscillating belt head allows uniform surface finish and longer belt life

-

Double pinch roller sets avoid edge chamfering during polishing

-

Available in both dry and wet models for flexibility

-

Compact and efficient design reduces power usage and labour costs

Applications:

-

Tube mills & railing fabrication

-

Rectangular and square metal tubing finishing in architectural, furniture, and construction industries

-

Decorative metal tubing for structural and aesthetic applications

-

Fabrication of transport vehicle and sheet metal tube profiles

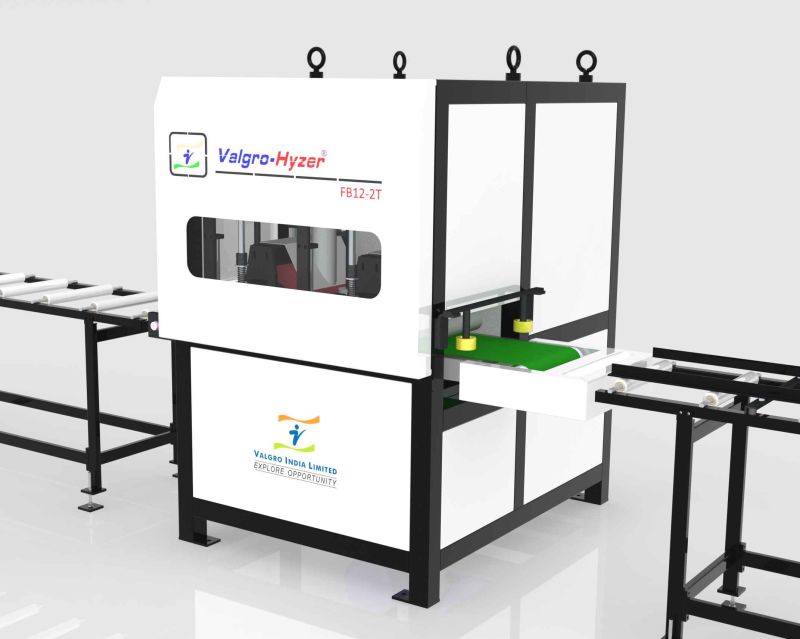

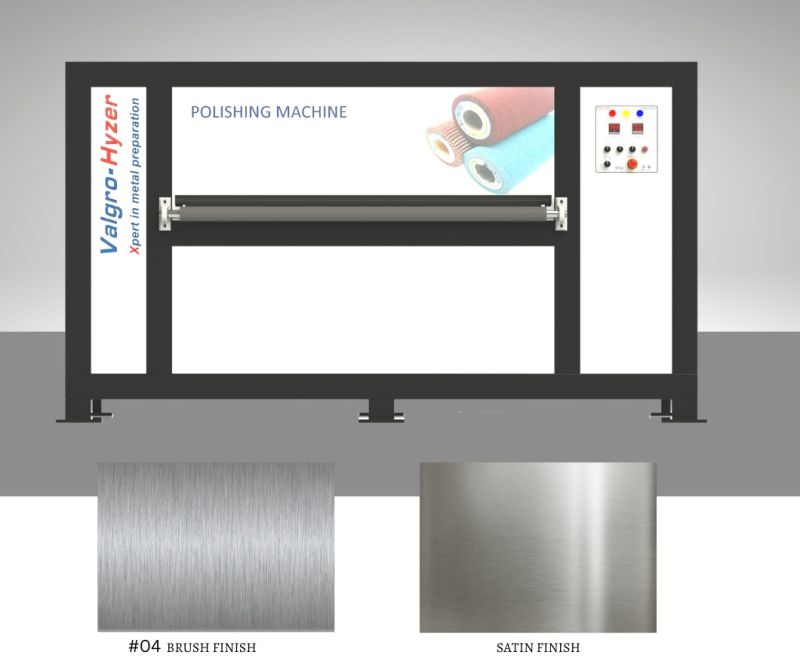

| Business Type | Manufacturer, Exporter, Supplier |

| Usage | Polishing Stainless Steel Sheets |

| Brand Name | Valgro India |

| Material | Stainless Steel |

| Type | Sheet Polishing Machine |

| Driven Type | Electric |

| Model | DB 50-1HD |

| Brush Diameter | 350mm |

Product Description:

The Valgro Fabrika Stainless Steel Sheet Polishing Machine is a precision-engineered finishing solution designed for medium-scale fabrication and metal-processing industries. It efficiently handles stainless steel, aluminum, and composite panels with thicknesses ranging from 0.8 mm to 3 mm. This dry-process machine offers uniform polishing, adjustable grinding pressure, and low maintenance, making it ideal for achieving professional surface finishes such as brush, satin, or mirror. Its compact design and in-house operation reduce labor, handling time, and production costs while ensuring high-quality, scratch-free results.

Key Features & Benefits:

-

Works with sheet thicknesses from 0.8 mm to 3 mm

-

Compatible with stainless steel, aluminum, and composite materials

-

Horizontal swing feed rollers ensure even polishing across surfaces

-

Adjustable grinding pressure for consistent finish quality

-

Dry process operation — clean, efficient, and eco-friendly

-

Compact footprint — ideal for small and mid-size workshops

-

Enables in-house finishing, reducing outsourcing and production delays

-

Ensures uniform surface finishing and enhances product appearance

Applications:

-

Kitchen and catering equipment manufacturing

-

Dairy, brewery, and food-processing plants

-

Pharmaceutical and medical equipment production

-

Architectural and building panel fabrication

-

Elevator, automotive, and instrumentation industries

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Phase | 3 Phase |

| Voltage | 415V |

| Type | Polishing Machine |

| Brand Name | Valgro India |

| Material Compatability | Brass, Copper and Stainless Steel |

| Coil Width | 50mm to 1600mm |

| Application | Polishing Metal Strip Coils |

| Power Source | Electric |

| Coil Thickness | 0.1mm to 4mm |

Product Description:

The Valgro Strip/Coil Polishing Machine is engineered for high-throughput finishing of metal strips and coils made of both ferrous and non-ferrous materials. It enables semi-continuous processing to remove scale, oxidation, and surface defects, while producing uniform satin, matt, or hair-line finishes. Designed for dry or wet operation, this system features heavy-duty construction, automated feed, and optional multi-head brushing for consistent, distortion-free output.

Key Features & Benefits:

-

Handles strip/coil processing of various widths (457 mm to 2134 mm) and materials including stainless steel and titanium

-

Multi-head brushing stations (4 or 6 heads) for scale removal, surface finishing, or corrective grinding

-

Adjustable conveyor feed speed from 0.5 m/min up to 20 m/min for process flexibility

-

Dry and wet operation options – wet lines include coolant recycling and filtration systems

-

Robust welded steel construction with dynamically balanced components for precision and stability

-

Suitable for producing brushed, satin, or decorative finishes and preparing strips for coating applications

Applications:

-

Surface preparation of coils for kitchenware, architectural panels, and decorative finishes

-

Finishing titanium and high-alloy strips in aerospace and defense industries

-

Pre-treatment of strip materials before anodising, coating, or bonding

-

Decorative and structural metal fabrication for furniture, appliances, and facades

Technical Summary:

-

Model Family: Strip/Coil Polishing Machine

-

Process Type: Dry or Wet (coolant-integrated)

-

Material Compatibility: Stainless Steel, Carbon Steel, Titanium, Aluminium, Non-ferrous Alloys

-

Capacity: Widths approx. 18″ (457 mm) to 84″ (2134 mm)

-

Feed Speed: 0.5 – 20 m/min

-

Heads: 4 / 6 multi-head configuration

-

Finish Capability: #3, #4, Satin, Hairline, Decorative

-

Brand: Valgro