manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

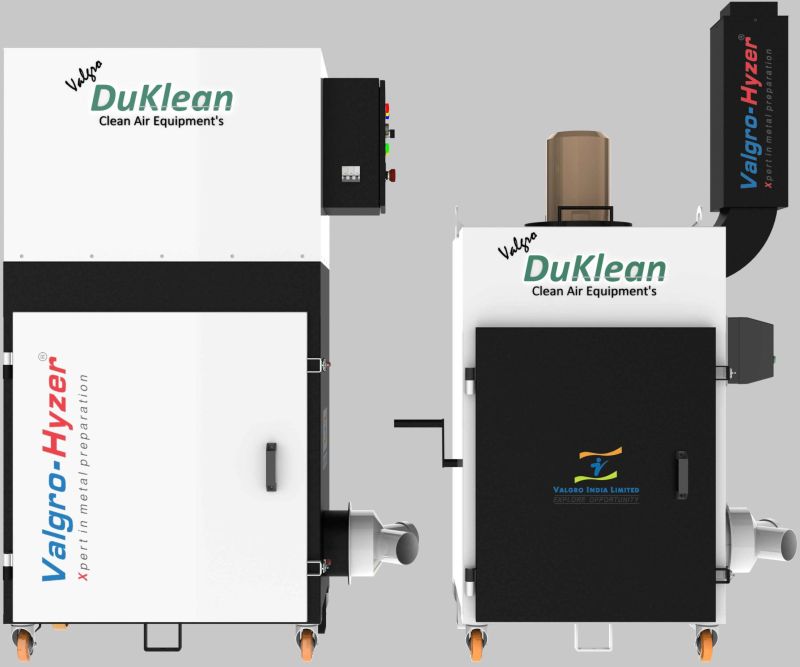

Dust Collection Machines

Leading Manufacturers, Exporters and Wholesaler of Valgro Down Draft Work Station, Valgro Mobile High-Suction Dust Collector Machine and Valgro Wet Dust Collector Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Work Station |

| Material | Stainless Steel |

| Usage | Capture Dust and Fume from Surface |

| Brand | Valgro |

| Power Source | Electric |

| Voltage | 220V |

| Wattage | 1000W |

| Additional Features | Down Draft Design For Efficient Dust Collection |

The Valgro Down Draft Table is engineered to protect operators’ health and improve productivity by capturing and removing dust, fumes, and airborne particulates generated during processes such as welding, grinding, sanding, or deburring. It provides a cleaner, safer, and more efficient work environment for industrial finishing operations.

OverviewThis down-draft workstation draws contaminants through a perforated work surface and side or back walls into an integrated exhaust and filtration system. The design ensures continuous airflow that effectively removes harmful airborne particles at the source. With its ergonomic height and modular configuration, the table can be customized for various industrial applications.

Key Features-

Efficient air suction through work surface, side, and back walls

-

Ergonomic and height-adjustable design for operator comfort

-

Modular construction available in multiple sizes and configurations

-

Easy disposal system for collected dust and debris

-

Spacious legroom for free movement and material handling

-

Ideal for processes like welding, deburring, grinding, sanding, and powder mixing

-

Reduces operator exposure to dust, fumes, and airborne contaminants

-

Improves workplace air quality and overall cleanliness

-

Enhances surface finishing quality by minimizing airborne interference

-

Flexible design supports multiple processes and operator needs

-

Promotes operator comfort and reduces fatigue with ergonomic design

-

Welding workstations (MIG, TIG, or Stick welding)

-

Deburring and grinding operations generating fine metal dust

-

Sanding and polishing of metals, plastics, or composite materials

-

Cutting, plasma, or laser operations producing smoke and fumes

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Dust Collector Machine |

| Brand | Valgro |

| Usage | Industrial Dust Collection |

| Model | DSC-1 |

| Filter Bas Size | 300x600mm |

| Noise Level | Less Then 70DB |

| Power Source | Electric |

| Voltage | 110-240V |

Elevate dust-control in your metal finishing environment with the Valgro Mobile High-Suction Dust Collector — a powerful, portable extraction system designed for demanding production lines, especially where sanding, grinding or brushing of metal generates fine particulate matter.

OverviewThis mobile dust collector features high-capacity suction, multi-stage filtration including HEPA- or cartridge-style filters, and a quiet operation design. With heavy-duty wheels for mobility, it can be moved easily between stations, making it ideal for dynamic workflows and multiple machines. It is particularly suited for metal shop applications where airborne dust must be captured right at the source to protect workers and finishing quality.

Key Features-

Portable design with heavy-duty wheels for easy repositioning and adaptability to different workstations.

-

High-efficiency filtration system capturing fine metal dust, including multi-stage filters (cartridge/HEPA) that ensure clean air return.

-

Powerful suction capability (high CFM airflow) to handle large dust loads from grinding, sanding or brushing operations.

-

Low-noise operation including an integrated silencer to enable a more comfortable and safer working environment.

-

Durable construction suited for industrial environments with heavy use, and simplified maintenance access for filters and collection trays.

-

Designed for integration with metal finishing machinery (belt sanders, deburring machines, polishing lines) to maintain cleaner workspaces and improve finishing consistency.

-

Improves air quality and reduces operator dust exposure, enhancing workplace health and safety.

-

Minimises downtime and improves machine longevity by preventing dust build-up in sanding/polishing equipment.

-

Enhances quality of finish by reducing airborne contamination and ensuring cleaner surface processing.

-

Because the unit is mobile, it adds flexibility and cost-effectiveness compared to fixed ducting systems.

-

Simplified maintenance with easy access to filters and dust collection components means lower operational overhead.

-

Metal-finishing shops using sanding, polishing or grinding on stainless steel, aluminium or other alloys.

-

Workshops or factories where multiple machines/worlds of production require dust extraction in different locations.

-

Any environment where fine metal dust (e.g., from brushing, grinding) poses health, fire or equipment‐life risks.

-

Production lines requiring regulatory compliance for dust exposure, airborne particulate control, or industrial housekeeping standards.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Dust Collector |

| Material | Stainless Steel |

| Noise Level | Less then 70DB |

| Usage | Industrial Dust Collection |

| Power Source | Electric |

| Brand | Valgro |

The Valgro Wet Dust Collector is engineered for industrial finishing environments where fine metal or combustible dust (e.g., aluminium, titanium, magnesium) poses significant safety and environmental risks. This wet-type extraction system captures dust through a water-bath filtration process, minimizing airborne particulates, reducing fire/explosion risk, and ensuring cleaner air and safer operation.

OverviewIn high-dust metal-finishing operations—sanding, grinding, deburring—traditional dry dust-extraction systems may struggle with fine metallic dust or combustible dust. The Valgro Wet Dust Collector uses a water-based capture method: dust-laden air is drawn into the unit and passes through a water bath where particles are trapped, safely contained and prevented from re-entering the air stream. This system is particularly effective in applications with combustible metal dust and requires corrosion-resistant construction, automatic water level control and low-maintenance design.

Key Features-

Wet filtration system: dust is captured in a water bath, preventing re-entrainment of fine particles

-

Designed for high efficiency dust capture in large-volume metal-finishing environments

-

Automatic water-level control to maintain optimum operation

-

Corrosion-resistant construction (PU coating or equivalent) for durability when handling abrasive or reactive dust

-

Low-maintenance design: removable trays and easy access to internal components

-

Explosion-proof design or safe for combustible dust applications such as aluminium, titanium and magnesium

-

Versatile for processes such as metal sanding, grinding, deburring, and where fine or hazardous dust is generated

-

Dramatically reduces fire and explosion risk by neutralizing combustible dust in a water bath

-

Improves air quality by capturing fine dust that would otherwise remain airborne

-

Enhances operator safety and regulatory compliance (industrial hygiene, environmental standards)

-

Extends equipment life by preventing dust accumulation inside finishing machines

-

Ideal for high-throughput operations needing robust dust-control solutions in metal-working environments

-

Metal-finishing lines where sanding, grinding or brushing of aluminium, titanium, steel or other alloys generates fine dust

-

Deburring or edge-finishing operations producing metallic particulate

-

Workstations or production lines where air-quality requirements or combustible-dust risks demand wet extraction

-

Fabrication shops, aerospace/automotive component lines, heavy-metal finishing operations where dust control is key