manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

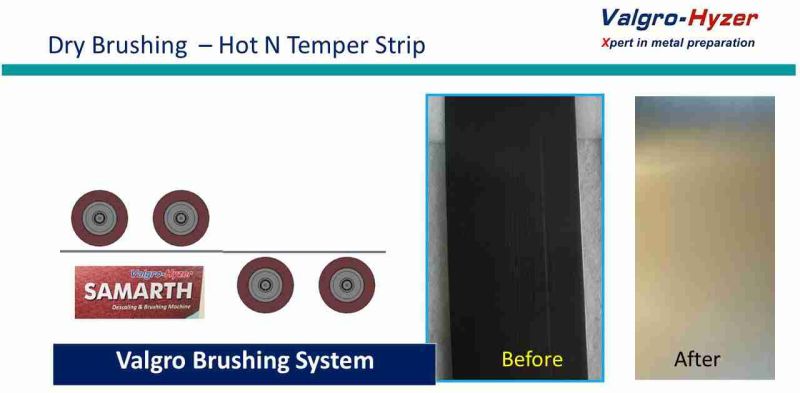

Harden n Tamper Steel Strip Polishing

Leading Manufacturers, Exporters and Wholesaler of Valgro Dry Brushing Hot Tempered Strip Machine, Valgro Dry Grinding Hard Temper Strip Machine and Valgro Wet Grinding Hard Temper Strip Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi Automatic |

| Type | Brushing Machine |

| Material Comptable | Stainless Steel |

| Noise Level | Less then 80DB |

| Application | Dry Brushing |

| Power Source | Electric |

| Brand | Valgro |

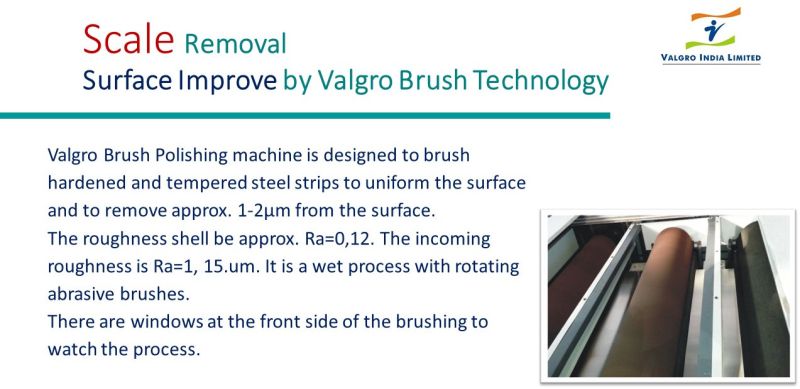

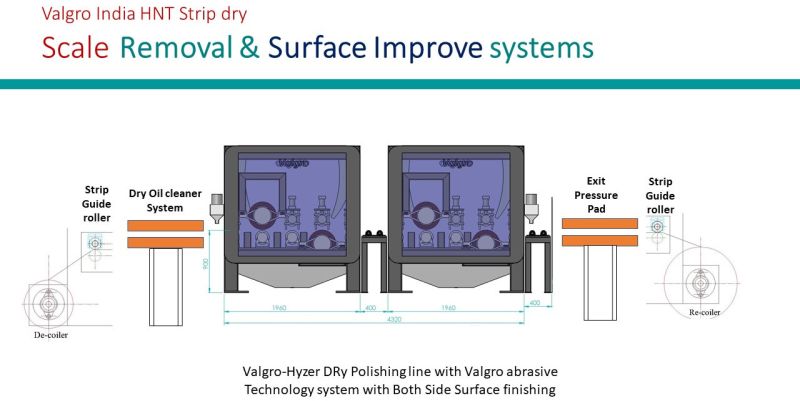

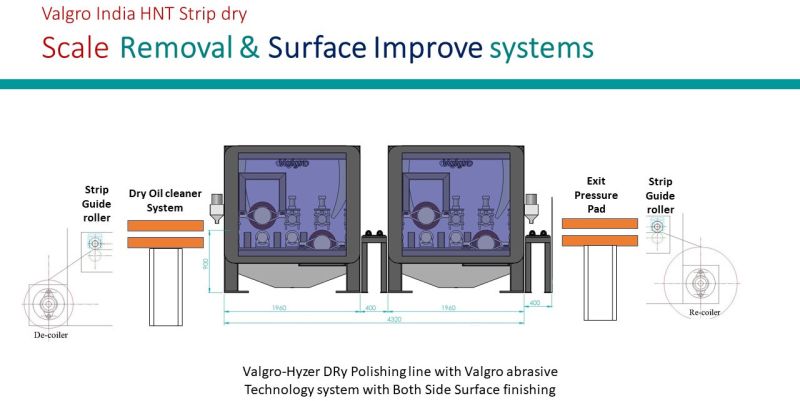

Elevate your strip finishing process with the Valgro Dry Brushing Hard & Tempered Strip Machine — designed to brush hardened and tempered steel strips in a dry process (i.e., without coolant) to achieve a clean, uniform surface with minimal removal.

OverviewThis machine applies heavy-duty rotating brushes to the strip surface to remove approximately 1-2 µm of material and reduce surface roughness (for example from Ra ~1.15 µm to ~0.12 µm) under dry operating conditions. It is built for robustness, vibration-free operation, and maintaining strip flatness (no camber or deformation) even as tough hardened or tempered strips are processed.

Key Features-

Dry brushing process: no coolant used, enabling operation in environments where wet processes are not practical.

-

Heavy brush chambers with sealed housings and viewing windows so operators can monitor the process.

-

Designed for no strip deformation / no camber, maintaining dimensional integrity of the material.

-

Vibration-free, smooth running, and engineered for uniform result from first metre to last.

-

Low-noise design (under ~80 dB) and energy-efficient operation.

-

Ideal for brushing hardened/tempered strips where scale, hardened surface layers or micro-irregularities need removal but coolant systems are undesirable.

-

Delivers consistent surface condition across full strip lengths, improving downstream processing reliability.

-

Reduces need for further finishing steps by achieving near-final surface quality in one pass.

-

Eliminates coolant handling, wastewater treatment, and some maintenance overhead associated with wet systems.

-

Helps preserve flatness and material geometry, critical for high-precision strip usage.

-

Suited for industrial scale strip processing with high throughput and minimal downtime.

-

Preparation of hardened or tempered steel strip for subsequent processing (coating, bonding, cladding).

-

Surface finishing for strips requiring very consistent, low-roughness surfaces before final manufacture in automotive, heavy engineering or precision components.

-

Environments where clean, dry processing is preferred (e.g., electronics, specialty steels, thin strip) or where coolant use is constrained.

-

Industrial strip lines needing brushing/de-scale plus surface refinement in one integrated step.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Semi Automatic |

| Noise Level | Less Then 80DB |

| Type | Grinding Machine |

| Material Comptable | Stainless Steel & Aluminium |

| Application | Dry Grinding |

| Brand | Valgro |

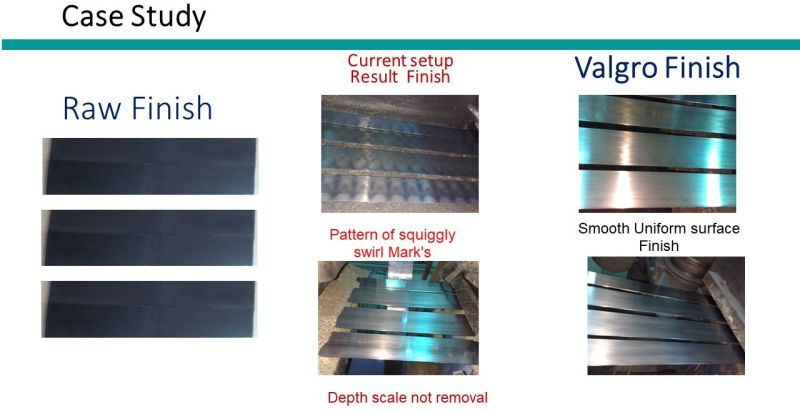

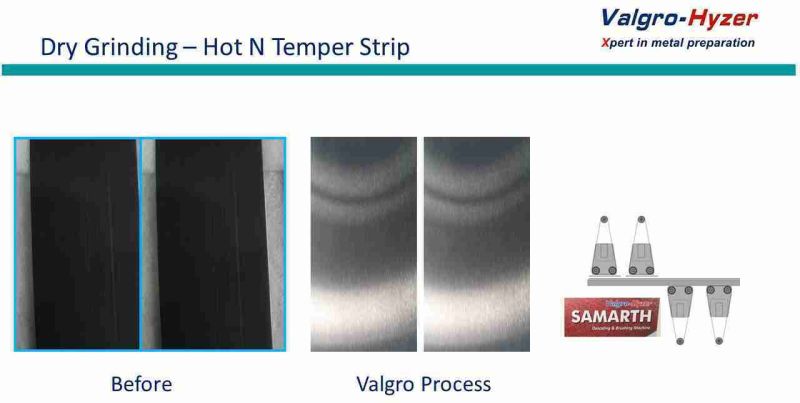

Enhance precision and surface quality in your strip processing line with the Valgro Dry Grinding Hard & Temper Strip Machine. This machine is engineered to grind hardened or tempered steel strips in dry mode with a robust dust-exhaust and filtration system, making it ideal where coolant processes are undesirable or impractical.

OverviewDuring the production of hot strips, surface defects such as scale, roughness, or micro-scratches often transfer downstream, affecting product quality. The Valgro Dry Grinding Hard & Temper Strip Machine removes these defects while preserving flatness and structural integrity. With its advanced dry grinding design, it ensures a clean, uniform surface suitable for cladding, coating, or further processing.

Key Features-

Designed specifically for dry grinding of hardened and tempered strips, featuring an efficient dust collection and filtration system

-

Vibration-free operation with uniform surface results from start to finish

-

Guarantees no strip deformation or camber, maintaining consistent flatness

-

Low-noise operation (<80 dB) with smooth and continuous feed performance

-

Energy-efficient system, minimizing power consumption and overall operating cost

-

Delivers consistent, high-quality finishes on hardened and tempered strips

-

Eliminates the need for wet coolant systems, ideal for facilities with cooling or wastewater restrictions

-

Reduces rework and scrap by improving surface condition before further processing

-

Supports high-throughput industrial strip processing with stable, long-term performance

-

Pre-finishing of hardened or tempered steel strips used in cladding, bearings, and electronic components

-

Surface preparation for ultra-flat, defect-free strips before coating, plating, or bonding

-

Suitable for heavy-duty strip processing lines where coolant use is limited or dry operation is preferred

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi Automatic |

| Strip Width | 2mm to 150mm |

| Strip Thickness | 0.2mm to 2mm |

| Type | Grinding Machine |

| Material Comptable | Stainless Steel & Aluminium |

| Usage/Application | Wet Grinding |

| Power Source | Electric |

| Brand Name | Valgro |

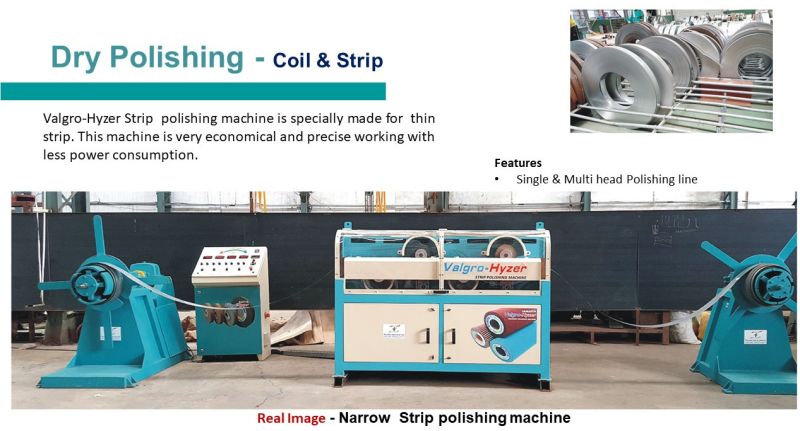

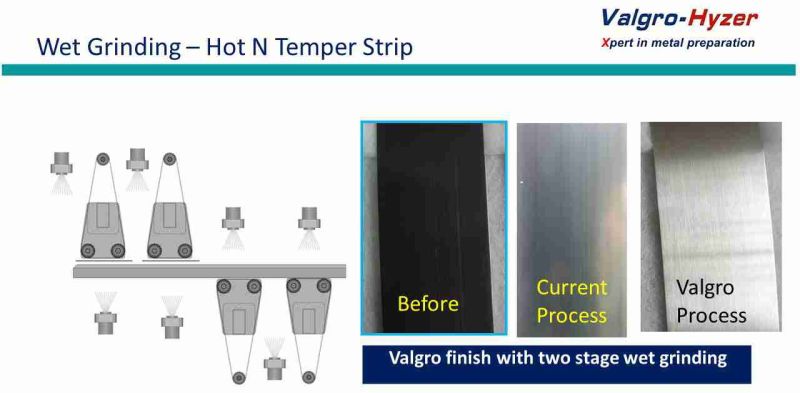

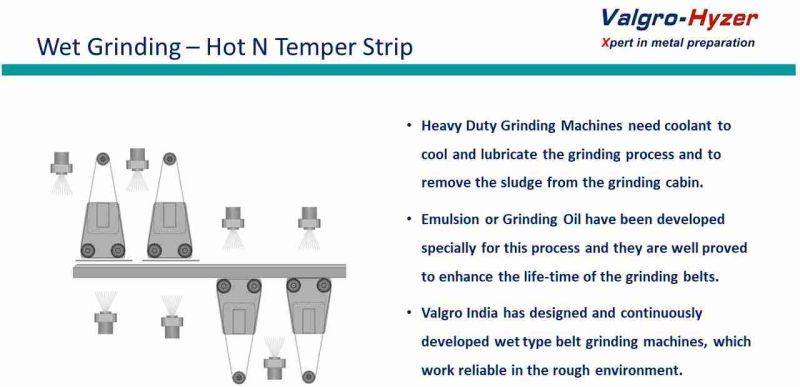

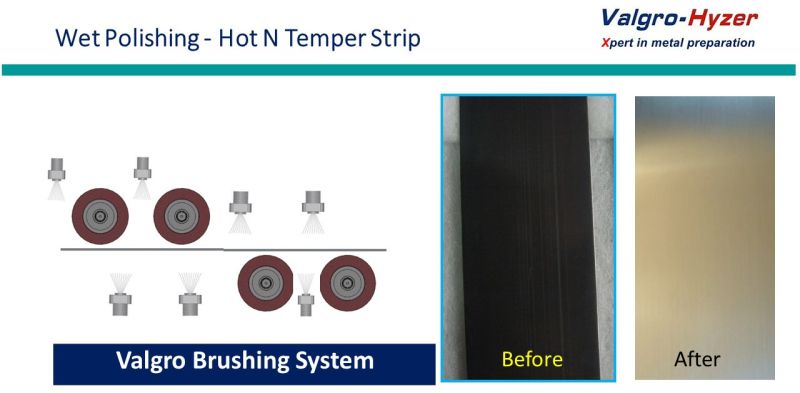

Enhance your strip surface quality with the Valgro Wet Grinding Hard & Temper Strip Machine, designed for precision grinding and surface improvement of hardened or tempered steel strips before further processing or roll cladding.

OverviewIn hot-strip production, surface defects like scale and irregularities can compromise downstream performance. The Valgro Wet Grinding Hard & Temper Strip Machine effectively removes these imperfections, delivering a clean, smooth, and uniform surface. This wet grinding system uses a coolant (emulsion or grinding oil) for controlled temperature and improved tool life — ideal for demanding industrial environments.

Key Features-

Heavy-duty belt grinding system designed for wet operation with coolant circulation and filtration

-

Efficient removal of scale, sludge, and surface defects during grinding

-

Guarantees no strip deformation or camber during operation

-

Vibration-free and stable performance, ensuring consistent finish quality

-

Low-noise operation (<80 dB) and energy-efficient design

-

Environmentally friendly with reduced dust and heat generation

-

Achieves consistent, high-quality surface finish across the full strip length

-

Maintains perfect flatness and prevents distortion during grinding

-

Increases downstream productivity and reduces rework

-

Improves belt life through effective cooling and lubrication

-

Ideal for continuous, industrial-scale strip processing

-

Grinding of hardened or tempered steel strips before further processing or cladding

-

Surface preparation for removing scale, oxide, or annealing coloration

-

Used in automotive, construction, and high-precision fabrication industries

-

Suitable for coil-to-coil or strip polishing lines where uniform finish is critical