manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

Precision Deburring Machine

Leading Manufacturers, Exporters and Wholesaler of Cross Belt Sanding Duburring Edge Breaking Machine, Samarth Series Brushing Machine, Valgro Classic Series Metal Deburring Finishing Machine, Valgro Edge Breaker Deburring Machine, Valgro Electrical Stamping Deburring Machine, Valgro Ez Series Entry Level Metal Deburring Finishing Machine, Valgro Hybrid Series Deburring Finishing Machine, Valgro Micro Strip Edge Deburring Finishing Machine, Valgro PLR Series Deburring Machine, Valgro SLR Series Laser Cut Deburring Edge Rounding Machine, Valgro Strip Edge Rounding and Polishing Machine and Valgro Tube Double End Edge Preparation Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Valgro India |

| Model Name | CBS Karma Series |

| Type | Sanding Machine |

| Material | Mild Steel |

| Usage | Sanding , Deburring and Edge Breaking Of Metal |

| Power Source | Electric |

| Roller Brush Diameter | 225x800mm |

| Conveyor Type | Belt Conveyor |

Product Discription:

The Cross Belt Sander – Deburring + Edge Breaking is a precision deburring machine designed to remove burrs and sharp edges from laser-cut sheet metal parts. It effectively handles various materials, including mild steel, stainless steel, and aluminum, ensuring smooth and safe edges. This machine is ideal for industries such as automotive, aerospace, and metal fabrication, where high-quality edge finishing is essential.

Key Features:

-

Efficient Deburring: Removes burrs and sharp edges from laser-cut parts, enhancing safety and quality.

-

Versatile Material Handling: Processes a wide range of materials, including mild steel, stainless steel, and aluminum.

-

Adjustable Conveyor Speed: Allows customization of processing speed to suit different materials and thicknesses.

-

Compact Design: Space-saving design suitable for various workshop environments.

-

User-Friendly Interface: Easy-to-operate controls for efficient machine setup and operation.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Industrial Deburring,Finishing,Cleaning Applications |

| Brand Name | Valgro India |

| Type | Brushing Machine |

| Material | Mild Steel |

| Model | Samarth DB Series |

| Power Source | Electric |

| Brush Diameter | 225mm |

| Power | 9.5hp |

Sheet Metal Parts Deburring & Finishing Machine

The Valgro Brushing and Deburring Machine efficiently removes microscopic scratches, acid coatings, and oxide layers from metal sheet surfaces. It offers a safer, faster, and more efficient alternative to traditional deburring systems, potentially eliminating manual deburring work. Designed for flexibility, Valgro offers multiple models to handle various sheet sizes and production needs while saving costs.

Benefits:

-

Deburrs thin parts without heat generation or deformation

-

Speeds up production, saving time

-

Maintains a clean and green working environment

-

Requires low space

-

Reduces labor and operational costs

Features:

-

Handles multiple thicknesses from 0.8 mm to 3 mm

-

Suitable for stainless steel, zinc, and aluminum

-

Eco-friendly and contactless process to avoid scratches

-

Can be integrated into existing production lines

-

Capable of deburring both small and large parts

-

Compact design for limited space units

-

Easy consumable replacement and maintenance

-

Robust, precise, and built with emergency safety switch

-

Designed to meet all safety standards

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Valgro India |

| Application | Deburing And Finishing Of Matel |

| Material | Mild Steel |

| Power Source | Electric |

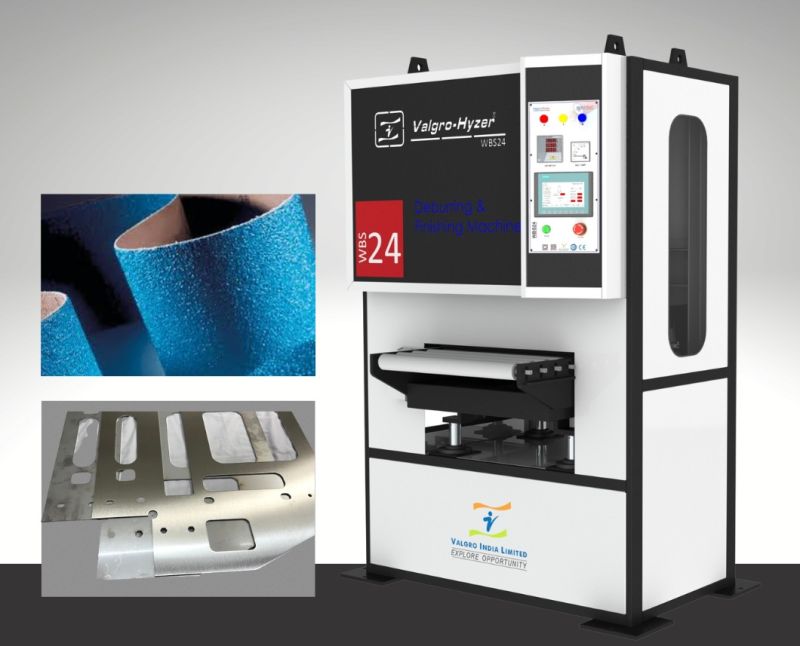

| Series | WBS 24-1 |

| Weight Capacity | 100kg |

| Conveyor Type | Roller |

| Adhrasive Blet Size | 1950 X 630mm |

Valgro Classic Series Deburring & Finishing Machine

The Valgro Classic Series is an affordable and versatile metal finishing solution designed for deburring, edge rounding, and surface finishing of sheet metal parts. It is suitable for various industries requiring efficient processing of materials such as stainless steel, aluminum, and mild steel.

Key Features:

-

Wide Belt Mechanism: Ensures uniform sanding and finishing over a large surface area.

-

Adjustable Pressure Settings: Allows for precise control depending on the thickness and type of material.

-

Advanced Filtration System: Captures dust and particles, ensuring a clean working environment.

-

User-Friendly Interface: Simplifies operation with easy-to-use controls and settings.

-

Safety Features: Includes emergency stop buttons, protective guards, and safety interlocks to ensure operator safety during operation.

Applications:

-

Deburring: Effectively removes burrs from metal parts to ensure smooth edges.

-

Edge Rounding: Rounds sharp edges to prevent injuries and improve the aesthetic appearance of parts.

-

Surface Finishing: Enhances the surface quality of metal parts for a polished look.

Ideal For:

-

Industries requiring high-volume processing of metal parts.

-

Businesses seeking a reliable and efficient solution for metal finishing tasks.

-

Operations aiming to improve the quality and safety of their products through effective deburring and edge rounding.

| Business Type | Manufacturer, Exporter, Supplier |

| Conveyor Type | Belt |

| Voltage | 220V |

| Power Source | Electric |

| Application | Deburring Metal Edges |

| Brush Diameter | 225mm X910mm |

| Material | Mild Steel |

| Model | Edge Breaker Series |

| Brand | Valgro |

| Type | Edge Breaker Machine |

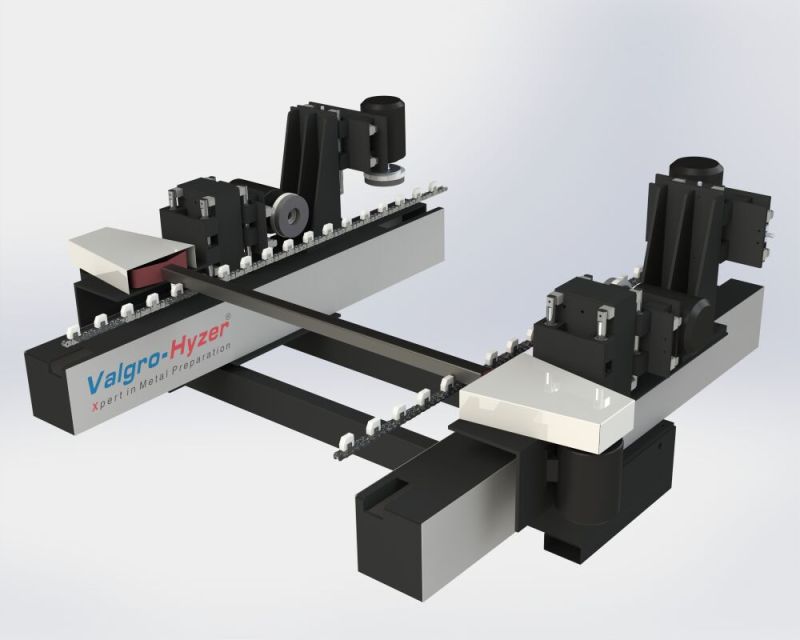

Valgro PLR Series – All-in-One Deburring, Deslagging & Edge-Rounding Machine

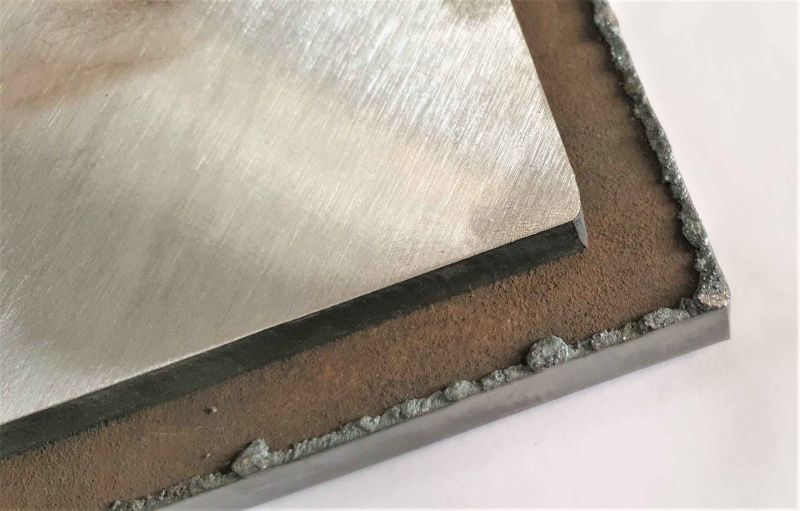

The Valgro PLR Series is meticulously engineered to meet the precise requirements of deslagging, deburring, and edge-rounding laser-cut sheet metal parts. This cutting-edge machine ensures superior edge quality and surface uniformity, making it an essential tool for modern manufacturing environments.

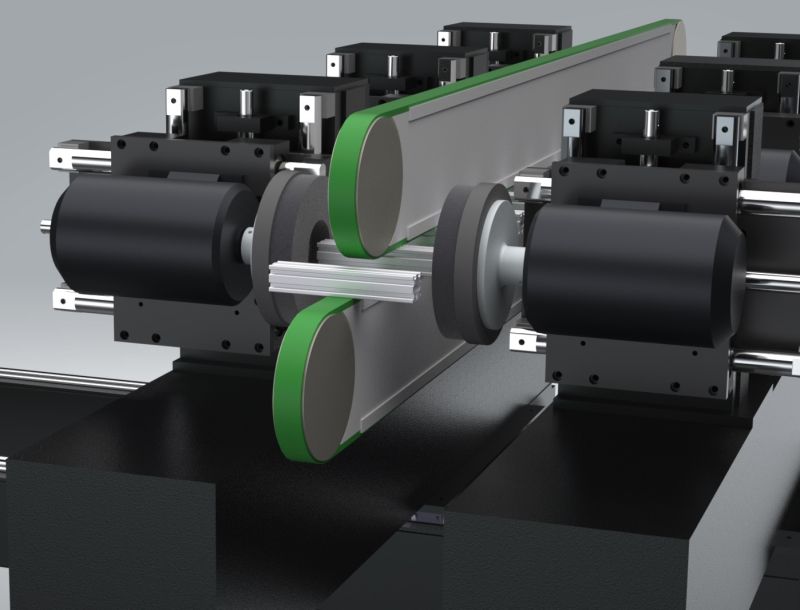

The PLR Series delivers comprehensive edge processing by precisely treating all inside and outside edges from multiple angles, resulting in a uniform and consistent finish. Its advanced design combines rotation and oscillation to produce a non-directional surface finish, making it ideal for a wide range of applications.

With customizable operation, operators can adjust variable disc RPMs and select different abrasive grit sizes for both clockwise and counter-clockwise rotation, providing unmatched adaptability across diverse material types. High flexibility is achieved through models equipped with three triple-planetary head units, enabling the machine to handle various deburring and finishing tasks with ease.

The compact, space-saving design allows seamless integration into industrial environments, even where space is limited. An intuitive, user-friendly interface simplifies setup and adjustment of processing parameters, ensuring optimal results for different materials and thicknesses. Engineered for high productivity, the PLR Series maximizes throughput by reducing cycle times while consistently maintaining superior quality.

Key Features:

- Multi-head oscillating planetary head mechanism: Ensures uniform sanding and finishing over a large surface area.

- Adjustable Pressure Settings: Allows for precise control depending on the thickness and type of material.

- Advanced Filtration System: Captures dust and particles, ensuring a clean working environment.

- User-friendly Interface: Simplifies operation with easy-to-use controls and settings.

- Separate electrical control for all functions

- Dry operation dust extraction system

- Easy abrasive replacement

- Adjustable conveyor speed

- Surface treatment is possible with different grit combinations

- Emergency security switch

Applications:

- Deburring and edge rounding of aluminum parts and thin sheet metal to heavy, thick plasma—or air-cut components.

- Slag and dross removal: Effectively removes residues from plasma and laser air-cut processes.

- Surface roughening: Ideal for aluminum frames or slightly deformed parts.

- Uniform finishing: Creates a consistent, non-directional surface finish.

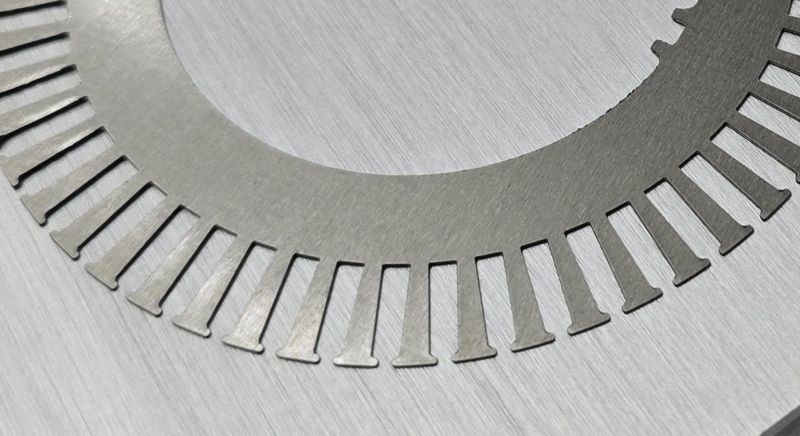

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Deburring Machines |

| Material | Mild Steel |

| Brand | Valgro |

| Model | EZ06-1 |

| Application | Electrical Stamping |

| Power Source | Electric |

| Brush Diameter | 110mm |

| Machine Weight | 800kg |

Valgro Electrical Stamping Deburring Machine

The Valgro Electrical Stamping Deburring Machine is engineered to efficiently remove burrs and sharp edges from electrical stamping parts, ensuring smooth and safe components for electrical applications.

Key Features:

-

Precision Deburring: Effectively removes burrs from electrical stamping parts, enhancing safety and performance.

-

Versatile Applications: Suitable for various electrical components, ensuring consistent quality across different parts.

-

User-Friendly Operation: Designed for easy integration into existing production lines, optimizing workflow efficiency.

Applications:

Ideal for industries such as electronics manufacturing, automotive electrical systems, and appliance assembly, where precise deburring of electrical stamping parts is essential.

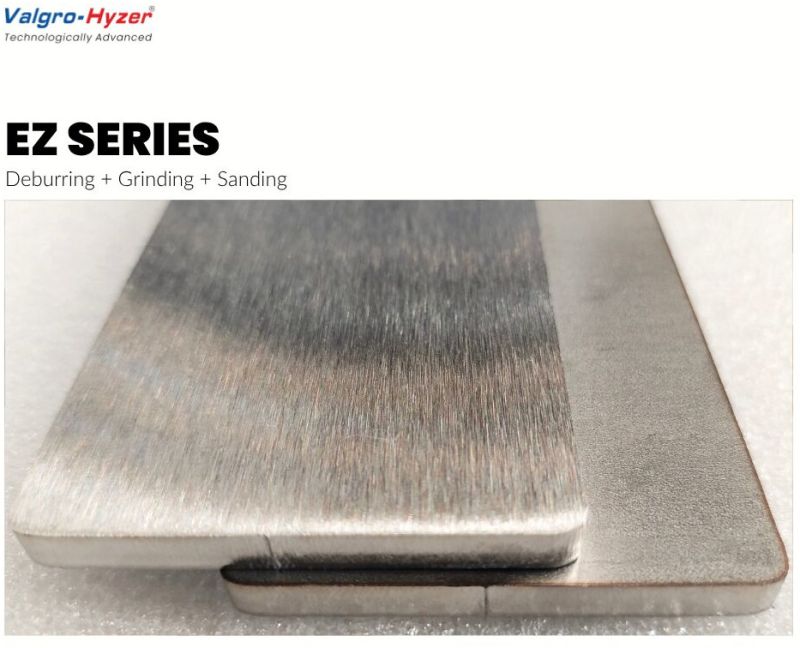

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Valgro India |

| Material | Mild Steel |

| Machine Weight | 1200kg |

| Power Source | Electric |

| Head Type | Belt |

| Model | EZ 24-1 |

| Working Head | 1 Head |

| Metal Thickness | 1mm to 75mm |

Valgro EZ Series Entry-Level Deburring & Finishing Machine

The Valgro EZ Series is an entry-level metal finishing machine designed for efficient deburring, edge rounding, and surface finishing of sheet metal parts. It is ideal for small to medium-scale operations seeking cost-effective solutions without compromising on quality.

Key Features:

-

Versatile Processing: Capable of handling various metal parts, including those cut by punching, shearing, laser, or plasma.

-

Efficient Operation: Utilizes a long belt sander mechanism to remove burrs and round edges effectively.

-

Adjustable Settings: Offers adjustable conveyor speed and sanding pressure to accommodate different material types and thicknesses.

-

User-Friendly Interface: Equipped with an intuitive control panel for easy operation and monitoring.

-

Compact Design: Space-saving structure suitable for workshops with limited space.

Applications:

-

Deburring: Effectively removes burrs from metal parts to ensure smooth edges.

-

Edge Rounding: Rounds sharp edges to prevent injuries and improve the aesthetic appearance of parts.

-

Surface Finishing: Enhances the surface quality of metal parts for a polished look.

Ideal For:

-

Small to medium-sized workshops.

-

Businesses seeking cost-effective metal finishing solutions.

-

Operations requiring efficient and reliable deburring and edge rounding capabilities.

| Business Type | Manufacturer, Exporter, Supplier |

| Application | Deburring And Finishing Of Matels |

| Model | Hybrid HYB 06-2 |

| Brand | Valgro India |

| Machine Material | Stainless Steel |

| Work Surface | Top Side |

| Working Head | 2 Head |

| Power Source | Electric |

| Brush Diameter | 225x150mm |

Valgro Hybrid Series – Deburring & Finishing Machine

The Valgro Hybrid Series is engineered to provide a comprehensive solution for deburring, edge rounding, and surface finishing of sheet metal parts. This versatile machine is ideal for industries requiring precise treatment of laser-cut, punched, and plasma-cut components.

Key Features:

-

Multi-Functionality: Combines deburring, edge rounding, and finishing processes in a single machine, streamlining operations and reducing equipment costs.

-

Wide Material Compatibility: Handles material thicknesses ranging from 0.8 mm to 12 mm, accommodating a variety of sheet metal parts.

-

Adjustable Conveyor Speed: Offers flexibility with adjustable belt/roller speeds from 0.5 to 12 meters per minute, catering to different processing requirements.

-

Dry Operation with Dust Extraction: Operates in a dry mode with an integrated dust extraction system, ensuring a clean and safe working environment.

-

Easy Abrasive Belt Replacement: Facilitates quick and efficient replacement of abrasive belts, minimizing downtime.

-

Emergency Security Switch: Equipped with an emergency stop switch for enhanced operator safety.

Applications:

-

Laser-Cut Parts: Efficient removal of burrs and slag from laser-cut components.

-

Sheet Metal Processing: Ideal for deburring and finishing sheet metal parts across various industries.

Advantages:

-

Enhanced Productivity: Streamlines multiple processes into a single machine, improving workflow efficiency.

-

Consistent Quality: Delivers uniform deburring and finishing results, ensuring high-quality output.

-

Cost-Effective: Reduces the need for multiple machines, lowering capital investment and maintenance costs.

-

User-Friendly Operation: Designed for ease of use, with intuitive controls and minimal maintenance requirements.

| Business Type | Manufacturer, Exporter, Supplier |

| Model | Micro Strip |

| Brush Diameter | 350mm |

| Power Source | Electric |

| Application | Finishing Edges Of Metal Strips |

| Brand | Valgro India |

| Material | Mild Steel |

| Type | Deburring Machines |

| Speed | 800 Parts Per Hour |

Valgro Micro Strip Edge Deburring Machine

The Valgro Micro Strip Edge Deburring Machine is engineered for precision deburring and finishing of narrow metal strips, particularly those produced through slitting processes. This specialized equipment removes burrs from both edges of thin metal strips, enhancing surface quality and safety.

Key Features:

- Processes strip thicknesses from 0.2 mm to 1.5 mm and widths between 3 mm and 8 mm

- High-speed operation, capable of deburring up to 800 parts per hour

- Suitable for stainless steel, aluminum, and copper

- Compact design for easy integration into production lines

- User-friendly controls with safety features including emergency stop and dust extraction

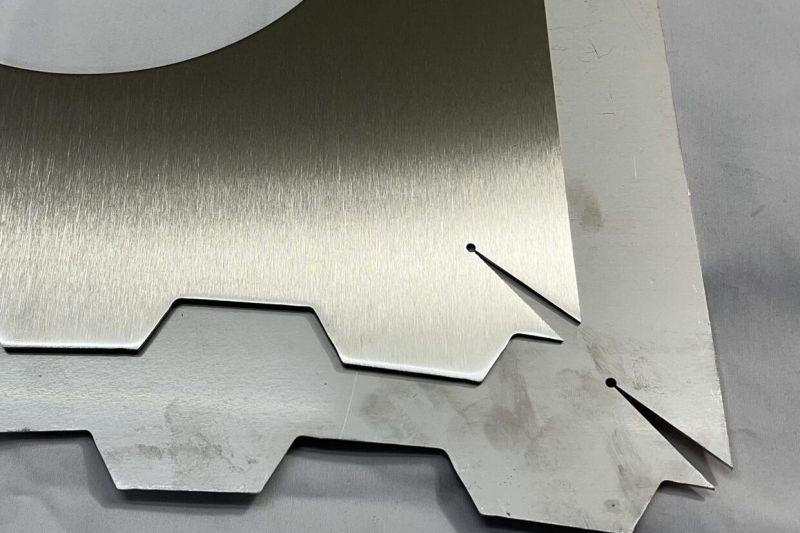

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Deburring Machines |

| Material | Mild Steel |

| Model | PLR Series |

| Brand | Valgro |

| Application | Industrial Plasma,Laser,Oxyburr Removal |

| Power Source | Electric |

| Brush Diameter | 250mm |

| Machine Weight | 1800kg |

Valgro PLR Series – Laser-Cut Sheet Metal Deburring & Edge-Rounding Machine

The Valgro PLR Series is meticulously engineered for deslagging, deburring, and edge-rounding laser-cut sheet metal parts, ensuring superior edge quality and uniform surfaces. Designed for modern manufacturing environments, it delivers precise edge processing by treating all inside and outside edges from multiple angles, producing a consistent, non-directional surface finish.

Its advanced multi-head oscillating planetary mechanism ensures uniform sanding and finishing across large surfaces. Operators can adjust disc RPMs, abrasive grit sizes, and pressure settings, offering unmatched adaptability for various materials and thicknesses. Models with triple-planetary head units provide high flexibility to handle diverse deburring and finishing tasks efficiently.

The compact, space-saving design allows seamless integration into industrial environments, while a user-friendly interface simplifies setup and operation. The PLR Series maximizes productivity by reducing cycle times without compromising quality.

Key Features:

- Multi-head oscillating planetary head for uniform surface finishing

- Adjustable pressure and conveyor speed for precise control

- Advanced filtration system for dust and particle capture

- Easy abrasive replacement and maintenance

- Separate electrical control for all functions

- Dry operation with dust extraction system

- Surface treatment possible with various grit combinations

- Emergency security switch for safety

| Business Type | Manufacturer, Exporter, Supplier |

| Usage | Deburing And Laser Cutting Of Mattel |

| Brand Name | Valgro India |

| Model Number | SLR 24-2 |

| Power Source | Electric |

| Material | Stainless Steel |

| Metal Waight Capacity | 300kg |

| Brush Diameter | 250mm |

| Machine Waight | 1800kg |

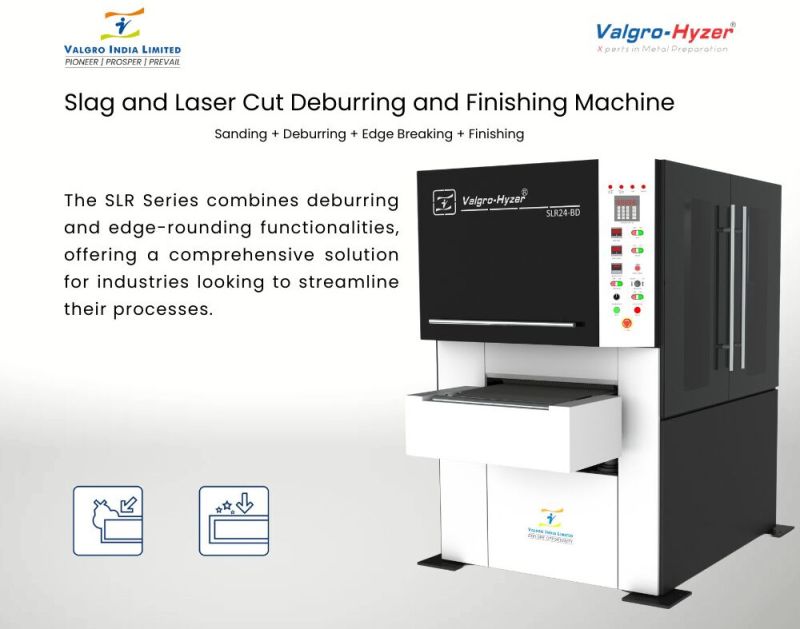

Valgro SLR Series – Laser Cut Deburring Machine

The Valgro SLR Series is engineered to efficiently remove burrs and scale from laser-cut, punched, and plasma-cut sheet metal parts. By integrating deburring and edge rounding functionalities into a single machine, it streamlines operations and enhances productivity.

Key Features:

-

Versatile Processing: Handles materials ranging from 1 mm to 75 mm in thickness, accommodating various production scales.

-

Customizable Configuration: Offers flexibility in the sequence of brush and belt heads to meet specific application requirements.

-

Advanced Features: Includes a vacuum table, magnetic track/bed, operator piece return system, and conveyor belt cleaning brush.

-

Efficiency: Replaces manual grinding operations, reducing operational expenses by up to 60%.

Applications:

-

Deburring: Effectively removes burrs from laser-cut, punched, and plasma-cut sheet metal parts.

-

Edge Rounding: Smooths sharp edges to prevent injuries and improve the aesthetic appearance of parts.

-

Surface Finishing: Enhances the surface quality of metal parts for a polished look.

Ideal For:

-

Industries requiring high-volume processing of metal parts.

-

Businesses seeking a reliable and efficient solution for metal finishing tasks.

-

Operations aiming to improve the quality and safety of their products through effective deburring and edge rounding.

| Business Type | Manufacturer, Exporter, Supplier |

| Voltage | 220V |

| Application | Industrial Metal Finishing |

| Brand Name | Valgro India |

| Material | Mild Steel |

| Power Source | Electric |

| Speed | 800 Parts per Hours |

The Valgro Strip Edge Rounding and Polishing Machine is designed to efficiently remove burrs and polish the edges of narrow metal strips. This machine enhances the safety and aesthetics of metal strips by rounding sharp edges and providing a smooth finish.

Key Features:

Processing Range: Suitable for strip thicknesses from 0.25 mm to 2.5 mm and widths ranging from 50 mm to 1550 mm, depending on the model.

High Productivity: Capable of processing a large number of strips per hour, improving manufacturing efficiency.

Versatile Applications: Ideal for various industries requiring precise edge rounding and polishing of metal strips.

User-Friendly Interface: Designed for easy operation and maintenance, ensuring minimal downtime.

Applications:

This machine is widely used in industries such as automotive, electronics, and precision engineering, where high-quality metal strips are essential.

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | Valgro India |

| Material | Mild Steel |

| Usage | Metal Tube Double End Edge Preparation |

| Driven Type | Electric |

| Type | Deburring Machines |

| Packaging Type | Cardboard Box |

| Model | DED04 |

| Work Surface | Double End |

| Brush Diameter | 350mm |

| Speed | 800 Parts per Hour |