manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

Polishing Machine

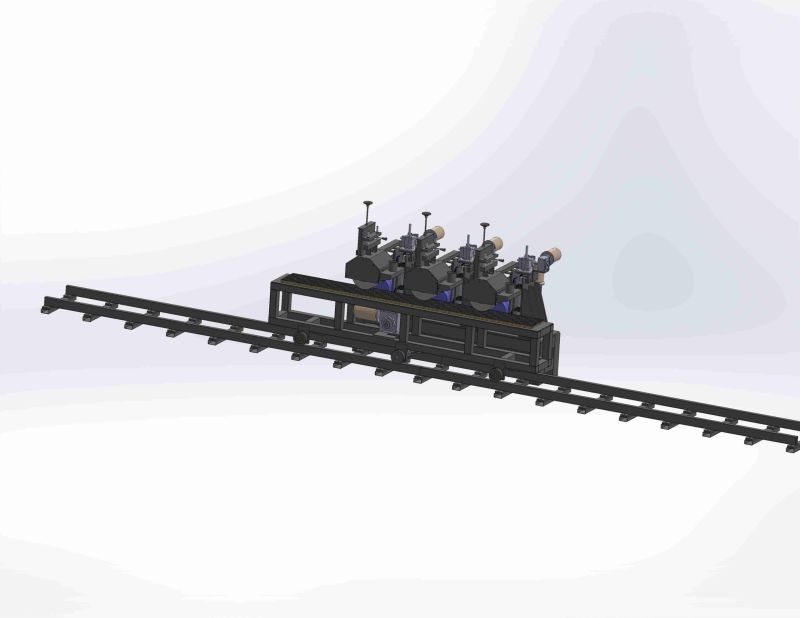

Leading Manufacturers, Exporters and Wholesaler of Valgro Coil to Coil Polishing Machine, Valgro High Gloss Mirror Polishing Machine, Valgro Large Plate Automated Polishing Machine, Valgro Sheet Coil Polishing Machine, Valgro Sheet Grinding Polishing Machine, Valgro Super 6K 8K Mirror Polishing Machine and Valgro Vibration Non Directional Finish Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polishing Machine |

| Material Comptable | Stainless Steel |

| Application | Coil To Coil Polishing |

| Power Source | Electric |

| Power | 300 HP |

| Width Capacity | 18 Inch to 84 Inch |

| Brand Name | Valgro India |

Product Description:

The Valgro Coil-to-Coil Polishing Line is designed for semi-continuous production finishing of metal strips and coils—both ferrous and non-ferrous. It features a heavy-duty structure, multi-head grinding and polishing system, and optional wet processing for consistent surface quality with minimal vibration and downtime. The system supports widths from 457 mm to 2134 mm and conveyor speeds from 0.5 to 20 m/min.

Key Features & Benefits:

-

Multi-head grinding/polishing station (4 or 6 heads) for high throughput

-

Wet or dry operation with coolant recycling option

-

Adjustable conveyor feed speed from 0.5 to 20 m/min

-

Handles wide material widths (18″ to 84″ / ~457 to ~2134 mm)

-

Robust welded steel frame and dynamically balanced components for stable, vibration-free operation

Applications:

-

Decorative surface finishing of stainless steel strips for architectural and appliance industries

-

Surface conditioning of titanium or non-ferrous strips for aerospace and industrial uses

-

Pre-treatment of strips for anodising, coating, or bimetal bonding

Technical Summary:

-

Model: Coil-to-Coil Polishing Line

-

Process Type: Dry or Wet

-

Material Compatibility: Ferrous (stainless steel) & non-ferrous (titanium, aluminium, etc.)

-

Width Capacity: Approx. 18″ (457 mm) to 84″ (2134 mm)

-

Feed Speed: 0.5 – 20 m/min

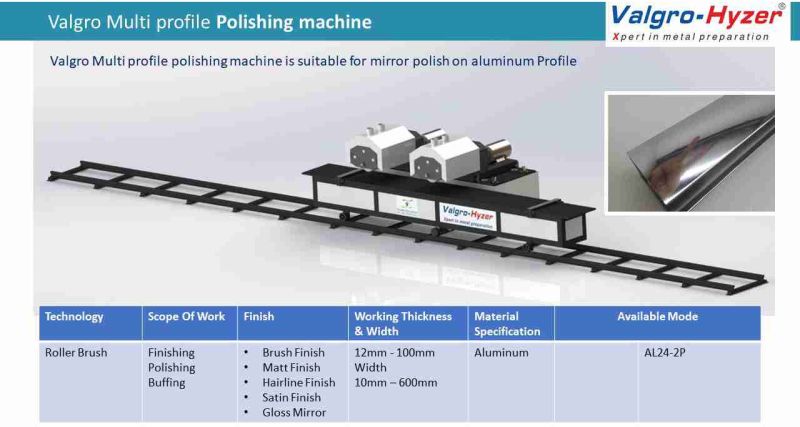

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Fully Automatic |

| Type | Polishing Machine |

| Material Comptable | Stainless Steel & Aluminium |

| Brand Name | Valgro India |

| Model | AL24-2P |

| Application | Mirror Polishing |

| Power Source | Electric |

| Voltage | 110-240V |

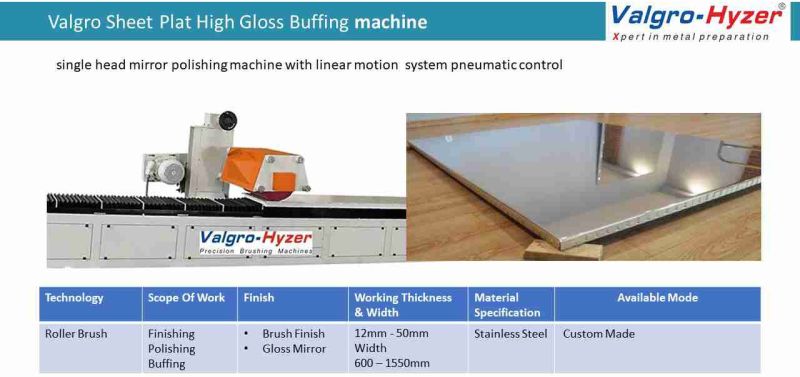

Achieve showroom-quality finishes with the Valgro High Gloss Mirror Polishing Machine — designed specifically for stainless steel sheets, aluminum profiles, and other metals that require ultra-bright, reflective “mirror-like” surfaces.

Overview

This high-performance polishing machine uses advanced buffing rolls (cotton, fibre, sisal, or steel wire) combined with a premium polishing compound to transform dull or rough metal surfaces into deep, high-gloss reflections. Through precise control of speed, pressure, and contact materials, it delivers a flawless mirror effect with minimal defects.

Key Features

Environment-friendly operation with minimal waste and clean process

High working efficiency with compact, space-saving design

Stable oscillation and vibration control ensure smooth, consistent finishing

Adjustable transmitting speed and polishing pressure to suit different materials and thicknesses

Quick change-over of polishing heads for flexible production runs

Built-in cleaning and drying unit ensures no watermark or residue is left post-lamination

Liquid compound recycling system reduces operational cost and prevents leakage

Benefits

Produces mirror-bright, blemish-free surfaces ideal for architectural, decorative, automotive, or appliance applications

Low operating cost and minimal maintenance make it cost-effective for high-volume production

Robust, heavy-duty build ensures long-term reliability in demanding environments

Suitable for both stainless steel and aluminum workpieces—versatile across multiple industries

Typical Applications

Polishing stainless steel sheets and plates to a mirror finish

Aluminum profile polishing for building facades, elevators, and furniture

Production of high-reflective components for architectural panels, signage, and luxury interiors

Any metal finishing line requiring high-gloss mirror quality instead of matte or satin finishes

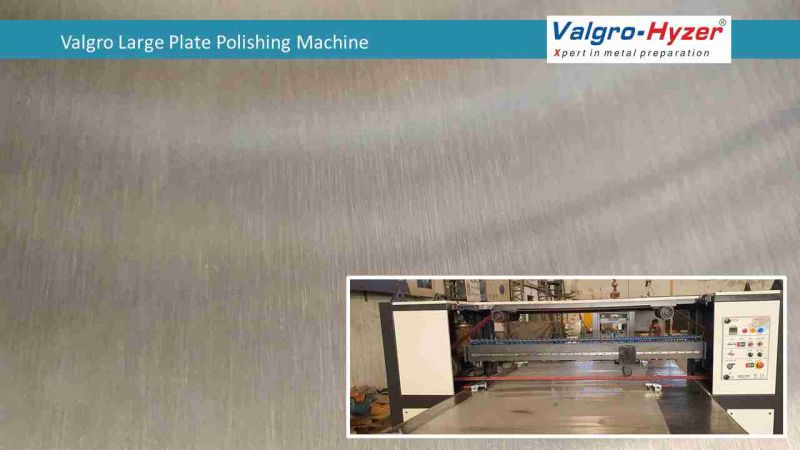

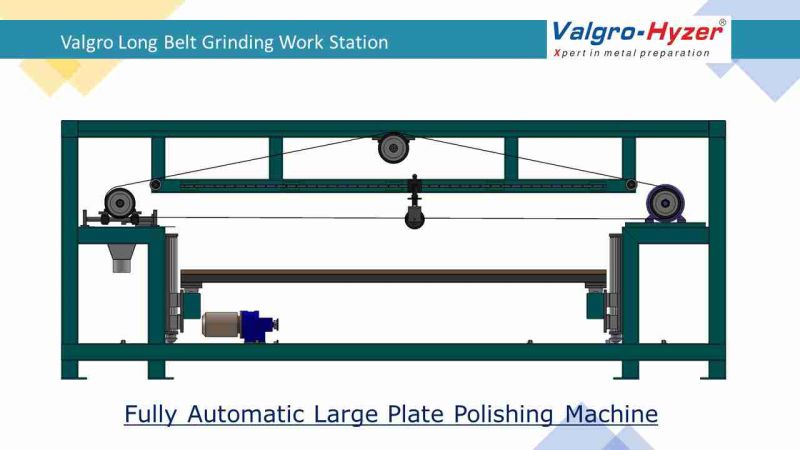

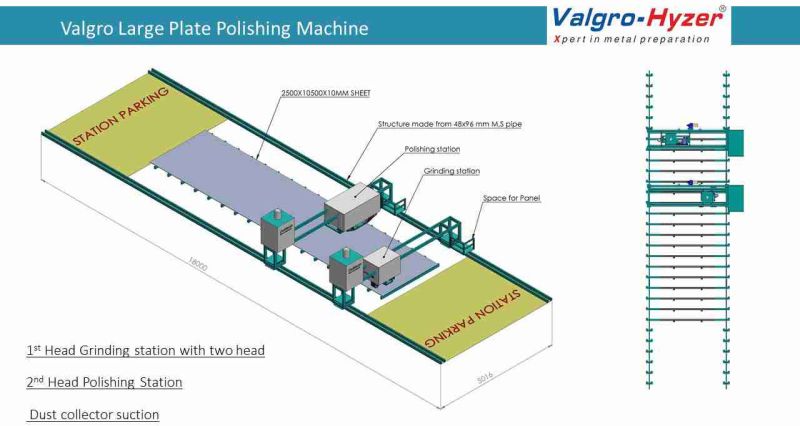

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polishing Machine |

| Metal Comptable | Stainless Steel & Aluminium |

| Brand Name | Valgro India |

| Application | Polishing Metal Plates |

| Automation Level | Fully Automated |

| Power Source | Electric |

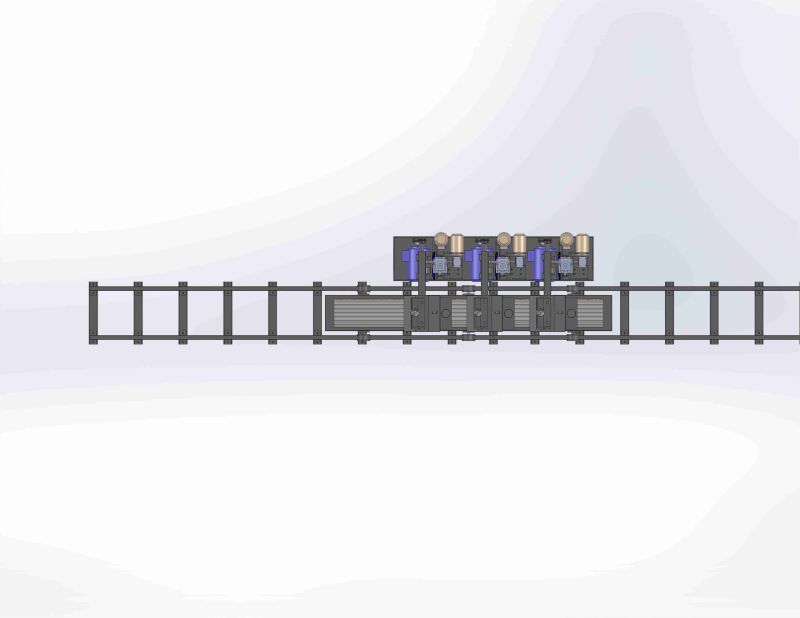

| Plates Dimension | 20 Mtr x 3 Mtr |

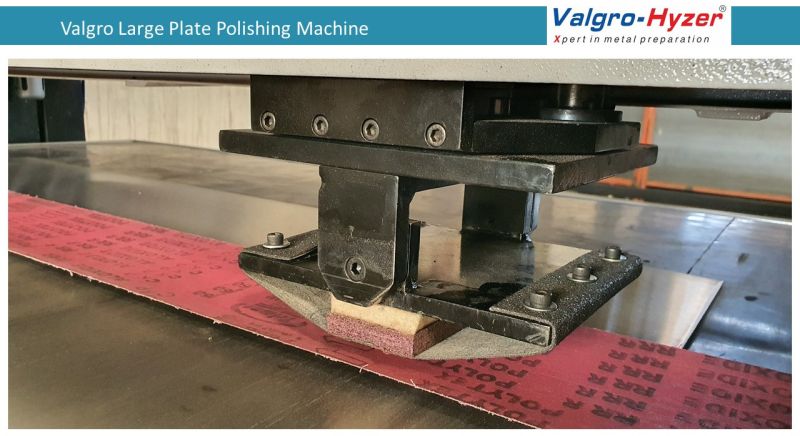

Transform large-format metal plates into precision-finished surfaces with the Valgro Large Plate Automated Polishing Machine — engineered specifically for heavy-duty metal sheets and plates that require high-quality finishing, large dimensions, and high throughput.

Overview

This automated polishing machine is designed to handle oversized plates, tubes, or sheets with widths and lengths beyond standard sizes. With its heavy construction and automated feed system, it processes large and heavy plates with exceptional speed, accuracy, and consistency — all while reducing operational costs. It is ideal where size, weight, and surface quality are equally critical.

Key Features

Capable of processing large plates up to several meters in width and length in a single pass

Fully automatic operation with feeding and conveying systems for safe, efficient handling

Adjustable conveyor speed to balance surface finish quality and throughput

Robust construction ensures vibration-free operation and consistent finishing results

Suitable for multiple materials including stainless steel, mild steel, and aluminium

Modular design allows quick tool changeover and high uptime for industrial production

Benefits

Enables large-format polishing with fewer steps and minimal manual intervention

Delivers smooth, uniform surface finishes across large areas with no patch marks or irregularities

Designed for heavy and oversized components used in architecture, shipbuilding, and fabrication

Reduces operator fatigue and labor cost with automated heavy-plate handling

Ensures long-term reliability and productivity in high-demand environments

Typical Applications

Polishing large stainless steel or mild steel plates for architectural panels and facades

Finishing aluminium plates for industrial or decorative applications

Preparing metal sheets for shipbuilding, heavy fabrication, or pressure vessel manufacturing

Ideal for any metal finishing operation requiring high precision on large or thick plates

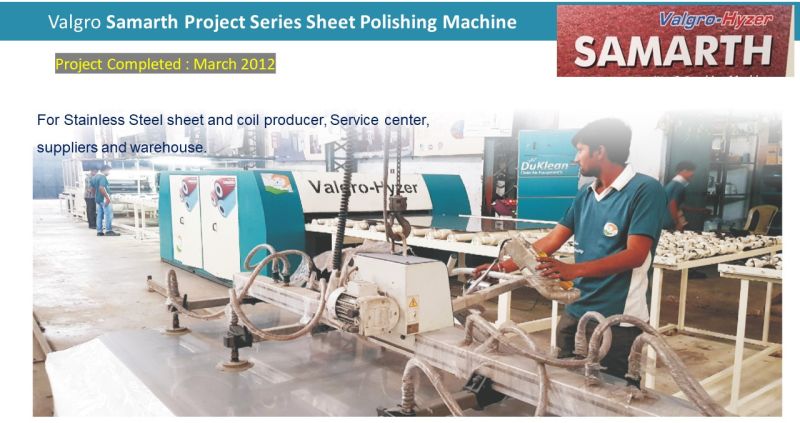

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Polishing Machine |

| Material Comptable | Stainless Steel and Copper |

| Head Type | Roller Brush |

| Brush Diameter | 350 to 400mm |

| Usage | Sheet And Coil Polishing |

| Power Source | Electric |

| Model | DB 50-1HD |

| Brand Name | Valgro India |

Product Description:

The Valgro Sheet/Coil Polishing Machine is a high-efficiency finishing system designed for processing metal sheets and coils to achieve smooth, bright, defect-free surfaces. Available in dry or wet variants, this machine accommodates variable widths and thicknesses, enabling industries to reduce handling, labor and chemical costs while delivering consistent brush, satin or hairline finishes for architectural, industrial and decorative applications.

Key Features & Benefits:

-

Multi-head brushing station with 4 or 6 heads for high throughput

-

Horizontal axis rotating and oscillating system for even surface finish

-

Supports both dry operation with dust extraction and optional wet processing

-

Adjustable conveyor feed speed (0.5–20 m/min) and brushing pressure

-

Easy abrasive head replacement, compact footprint

-

Results in rust-free, easy-clean surfaces, consistent finish, labor and time savings

Applications:

-

Kitchen equipment manufacturing, dairy & food-processing plants

-

Pharmaceutical machinery, public transport & rail systems

-

Elevators, automotive components, shipbuilding, architectural panel fabrication

Technical Summary:

-

Process Type: Dry or Wet polishing line

-

Material Compatibility: Stainless steel sheets/coils, aluminium, non-ferrous metals

-

Machine Features: Belt/roller transport; PLC control optional; emergency reversal safety

-

Finish Types: Brush, Satin, Hairline, #4 commercial finish

-

Brand: Valgro

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Grinding Polishing Machine |

| Speed(Adjustable) | 0.5 to 20 Miles per Min |

| Head Type | Roler head |

| Material Comptable | Stainless Steel |

| Usage | Sheet Grinding And Polishing |

| Power Source | Electric |

| Brand Name | Valgro India |

Product Description:

The Valgro Sheet Grinding & Polishing Line is a high-performance system engineered to process stainless steel sheets and coils in either dry or wet mode. It delivers premium finishes such as No. 3 (coarse), No. 4 (fine), or HL (hairline) by combining grinding and polishing in a single pass. With automated belt tracking, adjustable head pressure, and a powerful frame, it’s optimized for consistent finish, reduced labor, and minimal operational costs.

Key Features & Benefits:

-

Multi-head grinding & polishing station for efficient one-pass finishing

-

Horizontal axis rotating and oscillating polishing head for even surface treatment

-

Sheet auto-feed conveyor with variable speed (0.5–20 m/min) for flexible throughput

-

Adjustable polishing pressure and easy abrasive/brush head change for maintenance efficiency

-

Supports both dry and wet operation for versatile applications

-

Delivers rust-free, easy-clean, consistent surfaces – ideal for high-end finishes

Applications:

-

Sheet/coil finishing for stainless steel service centres and fabrication plants

-

Production of architectural panels, elevators, automotive parts, and food-industry equipment

-

Preparation of metal sheets for anodising, coating, or decorative finishes

Technical Summary:

-

Model: Sheet Grinding & Polishing Line

-

Process Type: Dry or Wet (oil/emulsion media possible)

-

Finish Outputs: No. 3, No. 4, Hairline (HL)

-

Material Compatibility: Stainless steel sheets/coils (hot or cold rolled)

-

Brand: Valgro

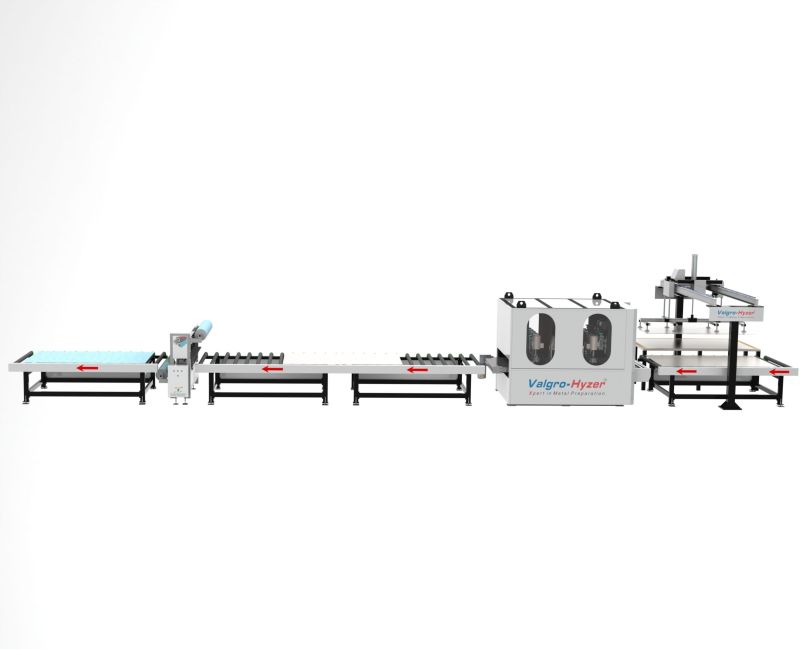

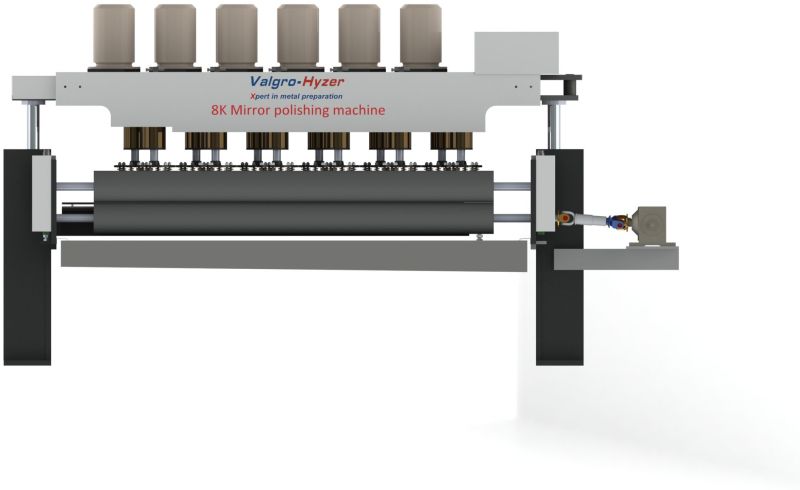

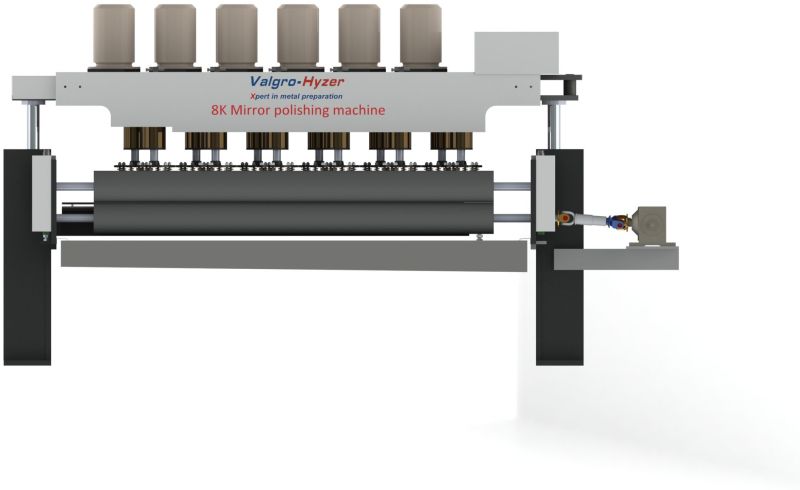

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Fully Automatic |

| Type | Polishing Machine |

| Material Comptable | Stainless Steel and Aluminium |

| Brand Name | Valgro India |

| Application | Metal Polishing |

| Power Source | Electric |

| Conveyor Type | Roller |

| Conveyar Speed | 0.5 to 1 Mile per Min |

| Model | Super 6K 8K |

Transform metal sheet surfaces into premium mirror-finish brilliance with the Valgro Super 6K/8K Mirror Polishing Machine — engineered for stainless steel sheets, aluminium panels, and demanding decorative metal applications.

Overview

This high-precision machine is designed to achieve ultra-bright “super mirror” finishes (6K or 8K grade) on metal surfaces by combining high-speed buffing spindles, oscillation or multi-head polishing arrangements, and precise surface pressure control. These finishes rival glass mirrors in reflectivity and are ideal for architectural, decorative, appliance, and signage metal components.

Key Features

Achieves 6K / 8K mirror-quality polishing with ultra-high reflectivity surfaces

Suitable for stainless steel sheets, aluminium sheets, and other metal substrates

High-speed rotating polishing heads with oscillation or multi-head configuration ensure uniform mirror finish across the width

Adjustable feed speed and pressure control to match sheet thickness and material type

Designed for high-volume production with reduced consumables and efficient finishing

Robust construction and durable components for consistent performance in demanding environments

Benefits

Produces flawless mirror-finish surfaces (6K / 8K level) that enhance the aesthetic and value of finished metal components

Reduces rework by achieving high-quality surface finish in one pass, improving productivity

Flexible for various substrates and thicknesses, ideal for builders, fabricators, and decorative metal processors

Perfect for premium interiors, elevators, facades, appliances, and signage applications

Typical Applications

Polishing stainless steel sheets to super mirror finish for wall panels, elevator interiors, and handrails

Finishing aluminium sheets or panels for architecture and luxury interiors requiring reflective aesthetics

Producing high-end signage or decorative metal components where visual quality is critical

Suitable for metal finishing lines that demand “super mirror” (8K) quality instead of matte or satin finishes

| Business Type | Manufacturer, Exporter, Supplier |

| Automatic Grade | Semi Automatic |

| API Width | 1000mm to 3500mm |

| Type | Vibration Finish Machine |

| Finish | Non-Directional |

| Driven Type | Electric |

| Application | Ideal For Finishing Metal Surfaces |

| Brand Name | Valgro India |

Product Description:

The Valgro Vibration & Non-Directional Finish Machine delivers a uniform, multi-directional scratch texture known as vibration finish (or non-directional satin/angel hair) on sheet, coil and plate surfaces. Suitable for stainless steel, zinc, aluminium and other metals, it processes thicknesses from 0.8 mm to 12 mm and widths up to 3 500 mm in a dry, contactless operation that avoids heat distortion and saves labour costs.

Key Features & Benefits:

-

Capable of thickness range from 0.8 mm to 12 mm

-

Compatible with multiple metals: stainless steel, zinc, aluminium and more

-

Eco-friendly dry process; no coolant required

-

Contactless handling to avoid scratches and deformation

-

Compact design for installation in smaller spaces

-

Minimizes labour and operational costs

-

Produces a high-density, consistent non-directional finish

-

No heat generation — avoids warping or distortion

Applications:

-

Luxury interior and exterior décor (elevator cabins, hotel lobbies, cladding, facades)

-

Architectural panels, columns, pillars, ceiling and wall cladding

-

Kitchen equipment, escalators and premium metal furniture

-

Tracks and components requiring low reflectivity, uniform texture

Technical Summary:

-

Finish Type: Vibration (non-directional satin/angel hair)

-

Material Widths: 1 000 mm to 3 500 mm (various standard widths)

-

Thickness Range: 0.8 mm to 12 mm

-

Form Factors: Coils, foils, strips, sheets, blanks, rings, etc.

-

Material Types: Stainless steel, zinc, aluminium, and other alloys

-

Brand: Valgro