manisha@valgroindia.com - GST NO. : 24AACCV5191L1Z0

- Send Email

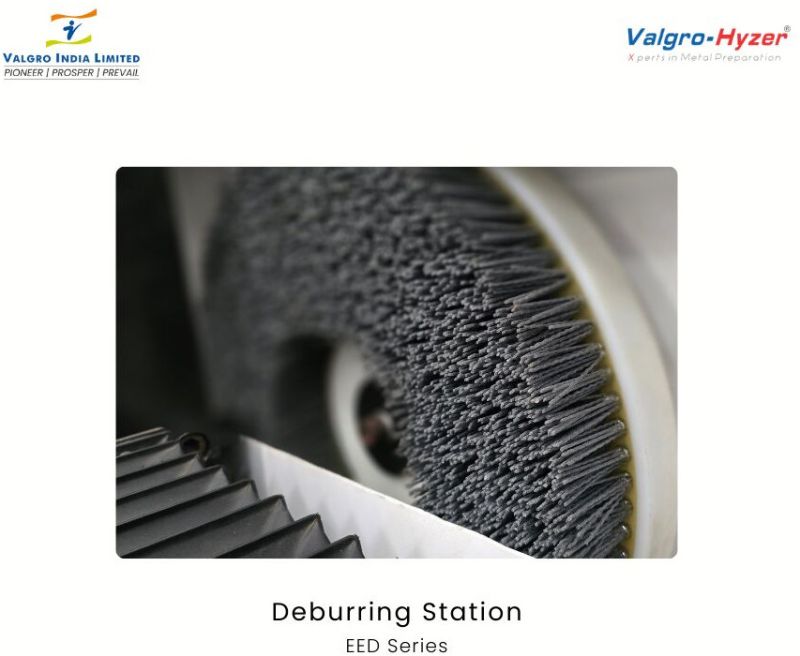

Compact Deburring Machine

Leading Manufacturers, Exporters and Wholesaler of Valgro Micro Joint Side Edge Deburring Machine, Valgro Profile Tube End Deburring Machine, Valgro Sheet Edge Preparation Machine, Valgro Tabletop Manual Deburring Machine and Valgro VBS Series Compact Deburring Machine from Ahmedabad.

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Deburring Machines |

| Material | Mild Steel |

| Brand | Valgro India |

| Model | Edge 9 |

| Application | Deburring Edges Of Metal Components |

| Power Source | Electric |

| Brush Diameter | 150mm |

The Micro Joint & Side Edge Deburring Machine is designed to eliminate micro-burrs on sheet-metal sides and edges caused by shearing and punching. It delivers clean, burr-free parts that are safe and ready for further processing.

Features:

Two deburring wheel stations act on the sides of the sheet

Top and side edge deburring using abrasive deburring wheels

Tilt-sheet conveyor allows flipping for both-side deburring

Automatic feed conveyor transport system

Easy abrasive replacement design

Equipped with emergency stop and variable conveyor speed control

Advantages:

Reduces manual effort and operator fatigue

Minimizes exposure to flying sparks, dust, and noise

Easy to operate, requires minimal training

Saves time and cost through faster processing and reduced downtime

Applications:

Ideal for thin-sheet metal processing industries requiring micro-joint removal, side-edge grinding, and top shear-edge deburring for precision finishing.

| Business Type | Manufacturer, Exporter, Supplier |

| Material | Mild Steel |

| Brand | Valgro India |

| Application | Deburring Tube Ends Efficiently |

| Machine Type | Tube End Deburring Machine |

| Model | EED14A |

| Power Source | Electric |

| Brush Diameter | 350mm |

| Working Head | 1 Head |

The Profile Tube End Deburring Machine is engineered to efficiently remove burrs from the ends of pipes, tubes, and various profiles, ensuring smooth and safe edges. Burr formation typically occurs after processes like shearing, punching, and cutting. Deburring is essential for enhancing aesthetics and eliminating sharp edges to ensure safety.

Key Features:

Versatile Edge Deburring: Suitable for round, rectangular, square, and other shaped edges, as well as various cut tubes and profiles.

Efficient Operation: Achieves deburring in seconds with a single operation.

Simultaneous Deburring: Handles both internal and external deburring simultaneously without pipe rotation.

Seamless Integration: Can be incorporated into a semi-automatic end-edge deburring system.

Safety Features: Equipped with an automatic clamp shell hood for additional protection against dust.

Variable Speed Drive: Powered by a 2 HP motor, compatible with either 12-inch or 14-inch Valgro disc deburring brushes.

Applications:

Ideal for industries requiring precision deburring of pipes, tubes, and profiles, ensuring smooth edges and enhanced safety in the final product.

| Business Type | Manufacturer, Exporter, Supplier |

| Driven Type | Electric |

| Automatic Grade | Semi Automatic |

| Type | Edge Preparation Machine |

| Material | Mild Steel |

| Brand Name | Valgro India |

| Model | Edge9 |

| Application | Industrial |

| Brush Diameter | 150mm |

The Sheet Edge Preparation Machine is designed for precise cut-edge processing after shearing. It efficiently removes burrs from the external perimeter of sheet metal, enhancing safety, appearance, and surface quality.

Key Features:

User-friendly design requiring minimal training

High efficiency: deburrs edges from shearing, punching, and other cutting operations quickly

Versatile application: compatible with stainless steel, mild steel, copper, brass, and aluminium

Safer workspace: minimizes operator exposure to sparks, dust, and noise

Time-efficient: saves money and labor compared to traditional methods

Applications:

Cut-sheet edge burr removal

Post-shearing edge preparation

Smooth finish of sheet metal external edges

Improves both appearance and safety by eliminating sharp or rough edges

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Manual Deburring Machine |

| Material | Mild Steel |

| Brand | Valgro India |

| Brush Size | 150mm |

| Application | Deburring Metal Workpieces |

| Power Source | Manual |

| Power | 3.8kw |

| Machine Weight | 205kg |

The Tabletop Manual Deburring Machine is a compact and efficient solution designed for precise deburring and edge-breaking operations in small workshops or moderate-production environments. It comes standard with a vacuum working table and two quick-change grinding heads — one brush disc and one sandpaper disc.

Key Features:

Adjustable speed for different deburring tasks

Vacuum clamping table to securely hold workpieces

Balance arm for stable, low-effort operation

Over three times faster than hand deburring

Equipped with dust drawer, extraction outlet, and safety features (including motor shutdown when the head is tilted)

Suitable for laser-cut, plasma-cut, and punched parts in steel, stainless steel, and aluminum

Works on material thicknesses from 1 mm to 150 mm

Technical Specifications:

Brush size: φ150 mm

Sand size: φ150 mm

Grinding head power: 0.22 kW

Total power: 3.8 kW

Machine footprint: 1100 × 710 × 1240 mm

Weight: 169 kg

| Business Type | Manufacturer, Exporter, Supplier |

| Type | Deburring Machines |

| Material | Mild Steel |

| Model | VBS09 |

| Brand | Valgro India |

| Application | Industrial Metal Fabrication |

| Power Source | Electric |

| Power | 3hp |

| Belt Size | 150mm x 915mm |

The Valgro VBS Series Compact Belt Grinder is designed for small-scale sheet metal industries seeking an efficient and precise deburring solution. Despite its compact size, it delivers powerful performance, making it an ideal choice for operations requiring high-quality results without occupying significant floor space.

Key Features:

Efficient Deburring: Effectively removes burrs from sheet metal parts, enhancing safety and finish quality.

Compact Design: Space-saving structure suitable for small workshops and production lines.

User-Friendly Operation: Easy to operate, reducing the learning curve and increasing productivity.

Durable Construction: Built with robust materials to withstand continuous operation in industrial environments.

Versatile Applications: Suitable for various metals, including stainless steel, aluminum, and mild steel.

Applications:

Ideal for industries such as automotive, electronics, and general metal fabrication, where precise deburring of sheet metal parts is essential.